Konecranes Portal

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, and spare parts, accessories and manuals.

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, and spare parts, accessories and manuals.

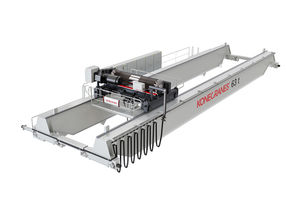

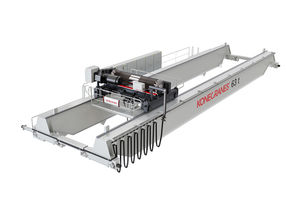

Cranes, hoists and warehouse automation plus service and parts for a wide range of industries.

Container handling equipment, mobile harbor cranes and lift trucks as well as software, service and parts.

We are trusted every day to lift, handle and move what the world needs.

Visiting from the U.S.?

Please choose: