Konecranes Portal

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, plus our store for spare parts, accessories and manuals.

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, plus our store for spare parts, accessories and manuals.

We live in a world of smart devices and your lifting equipment is no different. From remotely monitoring your crane usage and condition to ordering parts - digital tools bring crane information online, so it is easily accessible anytime and anywhere. Whether you’re on the production floor, in an office or on the road you can have visibility into maintenance activities and see how your cranes are performing no matter where you are.

The Konecranes Portal gives you the information you need to make informed crane maintenance decisions. A quick look at your service overview shows you open safety and production risks as well as TRUCONNECT condition alerts. Switching to the fleet view allows you to pinpoint which assets need the most attention.

The Konecranes Portal gives you the information you need to make informed crane maintenance decisions. A quick look at your service overview shows you open safety and production risks as well as TRUCONNECT condition alerts. Switching to the fleet view allows you to pinpoint which assets need the most attention.

The Konecranes Portal is also used in our customer consultation process. When we perform a Service Review we use the information on the portal to go over open risks, recommendations and quotations, answer your questions or concerns, and document next steps. You can also download your service report or share it by email.

When we conduct a Business Review with you – we will again use the Konecranes Portal to look at progress, discuss recommendations and plan jointly. These reviews can be conducted as an online meeting and you can access your review information at any time.

Learn more about Konecranes Portal

Remote monitoring is a key element of predictive maintenance and is used to collect equipment condition and usage data. Remote monitoring data is aggregated on the Konecranes Portal along with your inspection and maintenance data giving you a comprehensive view of equipment maintenance needs and performance.

Remote monitoring is a key element of predictive maintenance and is used to collect equipment condition and usage data. Remote monitoring data is aggregated on the Konecranes Portal along with your inspection and maintenance data giving you a comprehensive view of equipment maintenance needs and performance.

Analyzing and identifying anomalies, patterns and trends in TRUCONNECT data helps you make informed maintenance decisions and prioritize actions.

All your TRUCONNECT data is summarized on the portal per asset making it easy to see the current condition of the components, any risks related to safety and production, and the estimated remaining service life. Alerts call attention to safety and production issues such as emergency stops, overloads and motor overheating.

Usage details show how different crane operating patterns affect the safe operation and condition of the crane and the service life of critical components. Operating patterns can significantly influence the service life and safety of individual components.

Learn more about TRUCONNECT remote monitoring

Whether you need parts, manuals or even pre-configured lifting equipment, ordering online saves you valuable time.

Whether you need parts, manuals or even pre-configured lifting equipment, ordering online saves you valuable time.

The store on the Konecranes Portal features spare parts and accessories for many brands, makes and models of cranes and hoists; and selected pre-configured lifting equipment. You can also see parts inventory levels and lead times and track orders.

You can browse parts on the portal without a log-in. Registered users can access part pricing and availability, make purchases and trace orders as well as view manuals for your Konecranes lifting equipment.

Go to the Konecranes Portal

Crane users can quickly and easily record their findings when performing pre-shift and/or pre-lift inspections on CheckApp for Daily Inspections. Daily inspection records are accessible on the Konecranes Portal, where combined with maintenance history and condition data collected from selected components with TRUCONNECT Remote Monitoring, provides a comprehensive view of the condition of an asset in one easily accessible place. This data assists in planning maintenance actions and provides an audit trail of performed daily inspections.

Crane users can quickly and easily record their findings when performing pre-shift and/or pre-lift inspections on CheckApp for Daily Inspections. Daily inspection records are accessible on the Konecranes Portal, where combined with maintenance history and condition data collected from selected components with TRUCONNECT Remote Monitoring, provides a comprehensive view of the condition of an asset in one easily accessible place. This data assists in planning maintenance actions and provides an audit trail of performed daily inspections.

Learn more about CheckApp for Daily Inspections

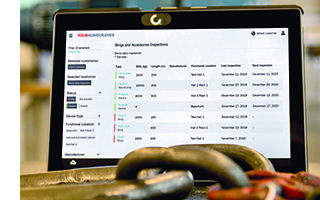

This inspection combines radio frequency identification (RFID) tags and a smartphone app to help you quickly and reliably identify attachments and record device inspection data. The inspection is performed by a competent technician who is trained and qualified and the information is then available on the Konecranes Portal. This gives you quick access to all relevant attachment information and an archive of inspection data to help you centrally manage your equipment. It also provides a record for regulatory requirements which can help you stay compliant.

This inspection combines radio frequency identification (RFID) tags and a smartphone app to help you quickly and reliably identify attachments and record device inspection data. The inspection is performed by a competent technician who is trained and qualified and the information is then available on the Konecranes Portal. This gives you quick access to all relevant attachment information and an archive of inspection data to help you centrally manage your equipment. It also provides a record for regulatory requirements which can help you stay compliant.

Learn more about the Slings and Accessories Inspection