Konecranes Portal

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, and spare parts, accessories and manuals.

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, and spare parts, accessories and manuals.

When it comes to choosing the right level of automation, it’s important to understand the nature of what you are machining as well as your specific requirements and capabilities. While fully automated systems can provide a cost-effective option, some applications may be more suited to semi-automation to meet production goals.

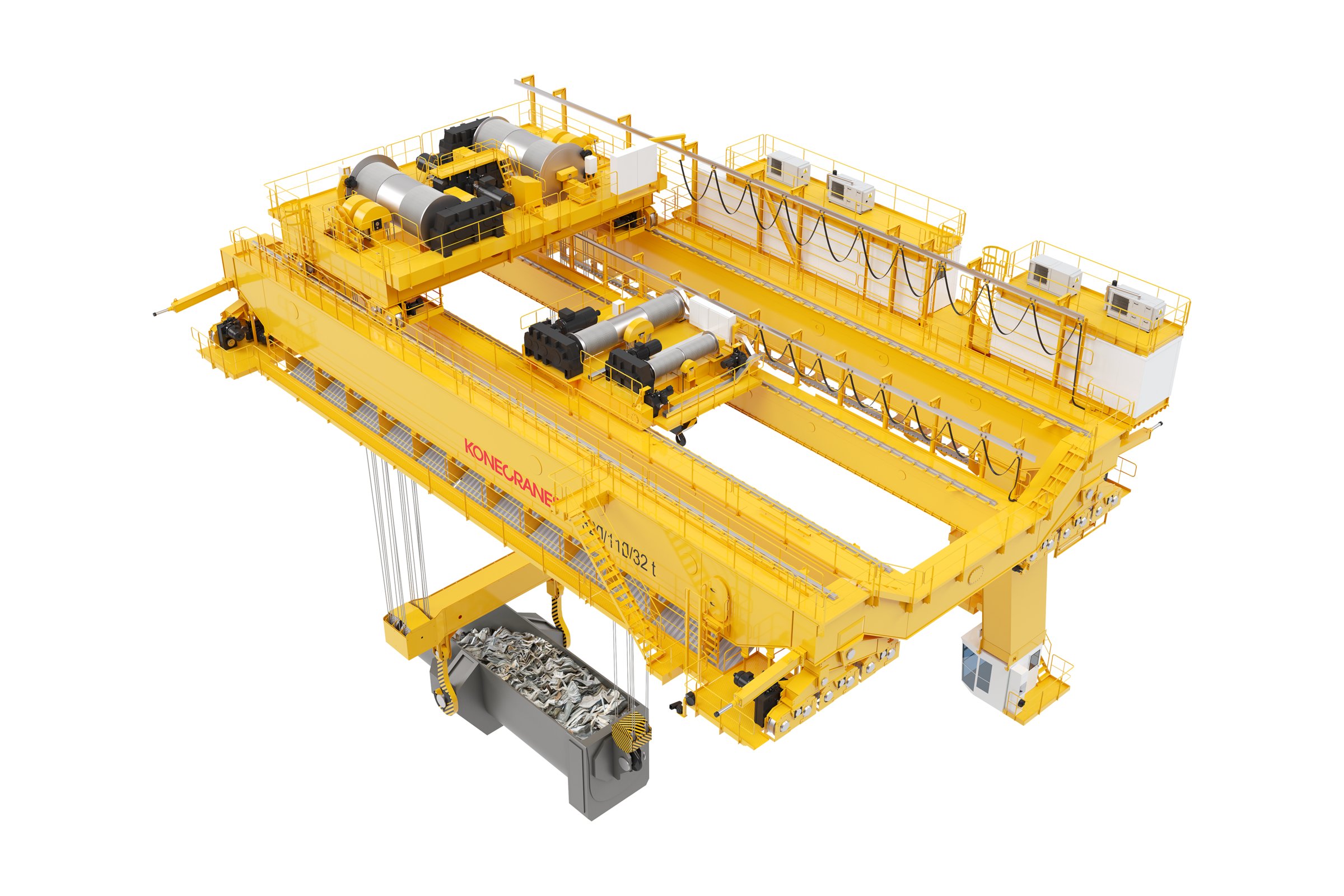

Semi-automation, currently more common in steel mills, involves an operator picking the load and then pressing a button to instruct the crane to deliver it to a pre-determined destination. Our cranes already include many features to help maximize safety and productivity. Movements and cycles are automatically controlled, minimizing human error. Konecranes Smart Features help improve safety, cycle times and load positioning, delivering major benefits when performing repetitive actions and are particularly useful on automated cranes.

In complicated processes such as charging, a semi-automated crane can make movements more quickly and smoothly. All the operator has to do is push a button for the crane to access the chosen bin. With the bucket perfectly centered over the bin, the crane lowers and grabs material. Then the operator presses a button programmed for the right furnace, and the crane follows the defined path to its destination. This is particularly good for new operators.

Load Control Features are designed to improve the crane operator's safety and productivity by making the crane move more smoothly and easily.

Electrical Active Inertia Control based on similar principles that Active Sway Control but is designed for long parts handling. The system consists of camera on trolley and reflector on the slewing part of the lifting device. The arrangement is additional system and Active Sway Control devices cannot be used for this purpose.

Sway Control limits the load swing that can lead to production delays and downtime. Without the distraction of managing sway, crane operators can focus on their surrounding environment to select a safe traveling path for faster load handling and more precise positioning.

A recent study confirmed that cranes with Sway Control are 60% faster than an ordinary crane.

Active Sway Control is available for standard duty biomass cranes only. It automatically eliminates load sway during crane operation. Based on the continual measurement of the rope angle, it fine tunes the operator’s speed commands and stabilizes load movement in both trolley and bridge travel. Minimal load sway throughout the duty cycle improves operational safety, load cycle times, ease of crane operation and reduces wear on crane components.

This feature is only available for CXT hoists

Shock Load Protection is designed for smooth load pickups and to prevent shocks to the load and the crane. It is a feature of Konecranes Variable Frequency Drives for hoist control. If a load is picked up too fast, the hoisting speed is automatically reduced until the load is raised. This protects the crane and reduces the risk of collision and damage to buckets, hoppers and pit walls. With this automated feature, the operator can focus on controlling the load, monitoring his or her environment and ensuring that the load remains secure.

Electrical Inertia control based on similar principles that Sway Control but is designed for long parts handling. It automatically stops the slewing movement to the desired position by the operator. No slewing of the load exists afterwards.

Electrical Active Inertia Control based on similar principles that Active Sway Control but is designed for long parts handling. The system consists of camera on trolley and reflector on the slewing part of the lifting device. The arrangement is additional system and Active Sway Control devices cannot be used for this purpose.

Sway Control limits the load swing that can lead to production delays and downtime. Without the distraction of managing sway, crane operators can focus on their surrounding environment to select a safe traveling path for faster load handling and more precise positioning.

A recent study confirmed that cranes with Sway Control are 60% faster than an ordinary crane.

Positioning and Area Control Features help the crane operator position the load more efficiently and accurately, as well as adapt the crane’s working area to the physical layout of your production line.

Target Positioning moves the load from one of eight home positions to one of 120 possible preset target positions within a predefined area. The crane slows down, stops and lowers the load at the set target point. Just one button automatically returns the crane to its home location.

The Konecranes Target Positioning feature has been designed to reduce cycle times and to enhance safety.

Protected Areas allocates up to 16 permanent “no-go” zones to limit the crane’s movements to preset working areas only. This feature maximizes crane operating space, while helping to reduce the risk of accidents, equipment collisions and load damage.

Target Positioning moves the load from one of eight home positions to one of 120 possible preset target positions within a predefined area. The crane slows down, stops and lowers the load at the set target point. Just one button automatically returns the crane to its home location.

The Konecranes Target Positioning feature has been designed to reduce cycle times and to enhance safety.

Protected Areas allocates up to 16 permanent “no-go” zones to limit the crane’s movements to preset working areas only. This feature maximizes crane operating space, while helping to reduce the risk of accidents, equipment collisions and load damage.