Customer story

A Crane makeover in 6 short weeks at a mainstream pumping station

Konecranes performed a complete and total crane makeover in only six weeks, giving the customer enough time to weather the rainy season ahead.

A weather-beaten, outdated crane

At our mainstream pumping station, our deep tunnel channel stores water overflow from storms. Our double-girder gantry crane is responsible for lifting the gate that regulates the water flow through the tunnel system. Above ground and completely outdoors, our crane was on its last legs: rusting, out-of-date and exposed to the elements. With the rainy season approaching, we needed to get this crane in top-running condition as soon as possible.

Konecranes dazzles us with much needed makeover

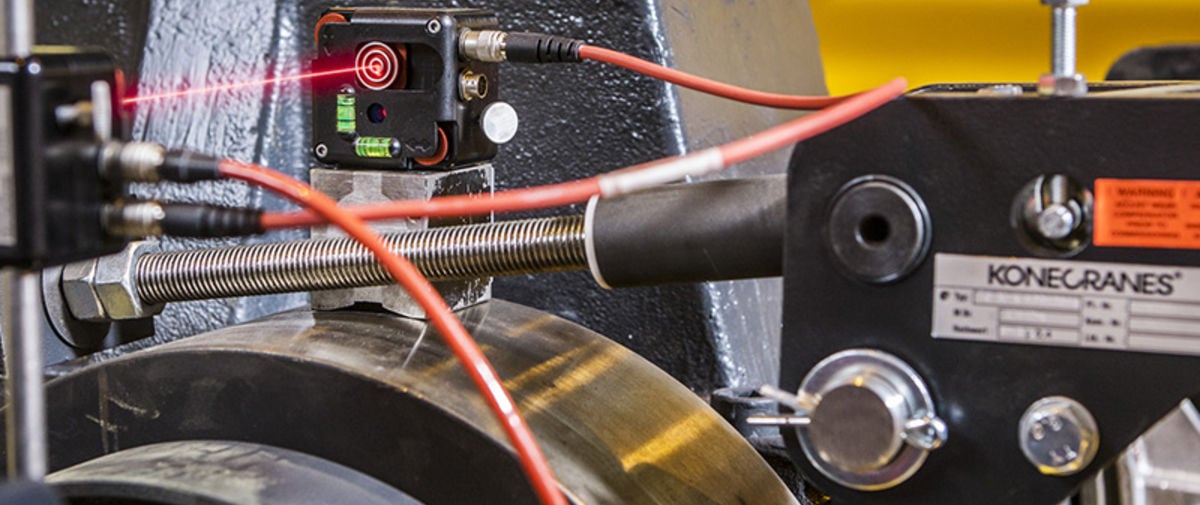

In just six short weeks, Konecranes gave our crane the makeover we desperately needed. With brand new inverter drives and brakes, the crane runs smoothly and more efficiently than ever before. Konecranes replaced our old, outdated control panels, which allows us to operate the crane with ease. Skilled technicians also weather-proofed the crane, changing everything to stainless steel and protecting the wiring. Konecranes also installed motorized wind locks, which monitor wind gusts and alert the crane operator to shut down if weather conditions are unsafe. Thanks to Konecranes, our crane is up and running in peak condition, and we’re ready to take on the rainy season!

Written from a customer's perspective