Login

yourKONECRANES.COM

Access your crane usage data from TRUCONNECT and maintenance data and asset details from MAINMAN on yourKONECRANES.com. Our cloud-based customer portal gives you a transparent view of service events and activities over any selected time interval.

Login

The Crane Pro Parts STORE

The Crane Pro Parts STORE is your single online source for parts for all crane makes and models. Get access to quick parts ordering, pricing, inventory, lead times and manuals.

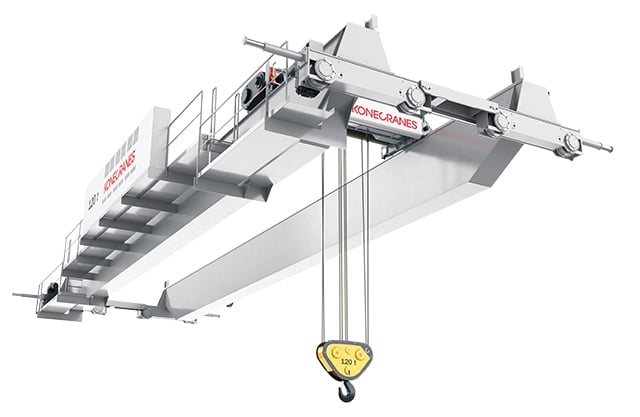

ically for the accuracy and smooth movements needed in assembly and maintenance. An outstanding achievement of advanced mechanical and electrical engineering, SMARTON has been adopted by many of the world’s leading industrial companies because it offers the right mix of mechanical excellence, lifting intelligence and service support.

ically for the accuracy and smooth movements needed in assembly and maintenance. An outstanding achievement of advanced mechanical and electrical engineering, SMARTON has been adopted by many of the world’s leading industrial companies because it offers the right mix of mechanical excellence, lifting intelligence and service support.