Digital twins have showed up in the technology trends lists over the last few years. There are more and more digital twin implementations appearing, and it’s getting clear that there will be billions of things represented by digital twins within the next years. Originated in the development of IoT, the digital twin refers to the virtual replica of the device, process or service, and it is capable of simulating the natural use, behavior and work process in real time. Digital twins provide multiple possibilities for companies to utilize the virtual model and collected data in engineering, testing, product development, service and sales.

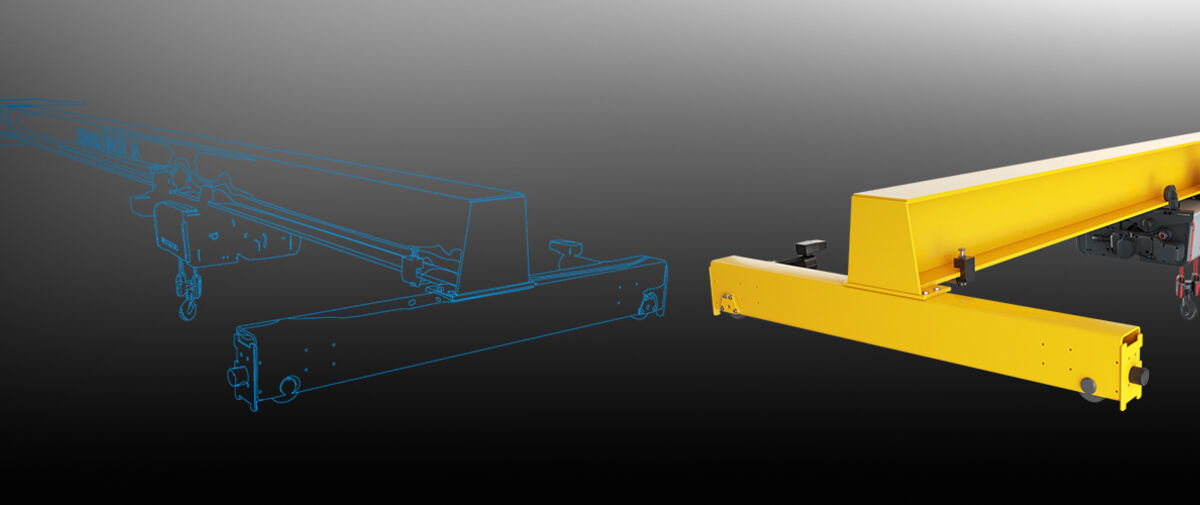

Technologies for digital twin mainly exists but there is still a lot to examine before all the potential of digital twin is easily utilized in large-scale for companies of different industries. Aalto University together with Konecranes, Siemens, Ideal PLM, Remion and RD Velho are developing digital twin concept with the aim of boosting Finnish manufacturing industry. DigiTwin research project focuses on the connecting of an overhead crane and its digital twin with product configuration, product design, and product life cycle.

-

Way of getting innovations faster to markets

Petri Asikainen, Konecranes Director of Core Technology Development, says that the collaboration with Aalto University Industrial Internet Campus (AIIC) and mid-size and small companies gives a possibility to utilize ecosystems and partnerships to get innovations faster to markets.

Collaboration enables us fast access to the latest research information, and in return, we can provide real industrial use cases for the AIIC community. Digital twin is a really good way to handle information in numerous use cases that we have and will have in the future. It can deliver results for sales, service and engineering. In that sense the digital twin is a multi-useable platform to be developed, Asikainen describes.

Better-optimized cranes and service for customer’s needs

Analyzing the data of a digital twin helps, for example, to predict faults and lifecycle of the device, and that how to minimize downtime and plan predictive maintenance. The data on how customers have used the cranes gives important information for product developers to optimize more precisely solutions that fit for the customer.

Despite the industry or the use of a crane, our target is always to minimize the total cost of ownership. When reaching that, it is good that everything – from engineering to service – is made by the optimization point that gives best value to our customer, Petri Asikainen says.

Product developers need often to find the information from many sources. In the future it can be possible that product designers can get the user data straight from the digital twin, Heikki Laaki, Doctoral Candidate of Aalto University tells.

At the moment, the researchers of DigiTwin project are studying: how to predict the remaining lifetime of a component from its digital twin, and how could maintenance personnel use augmented reality to access information of machines.

Who can access the digital twin data?

The Ilmatar crane, that we donated to Aalto University in 2016, has been used as the main development platform of the DigiTwin project.

With all digital twins, it’s crucial for companies to decide the rules and limits who can access the digital twin data. We announced that together with Aalto University we will gradually turn the Ilmatar crane development environment to an open platform for the Aalto Industrial Internet Campus community.

It’s important for us to enable open platforms that ease the collaboration between developers. In that way we can speed up the actual development work and help everybody to bring new products and features to markets, Petri Asikainen explains.

Learn more about predictive maintenance