Konecranes Portal

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, plus our store for spare parts, accessories and manuals.

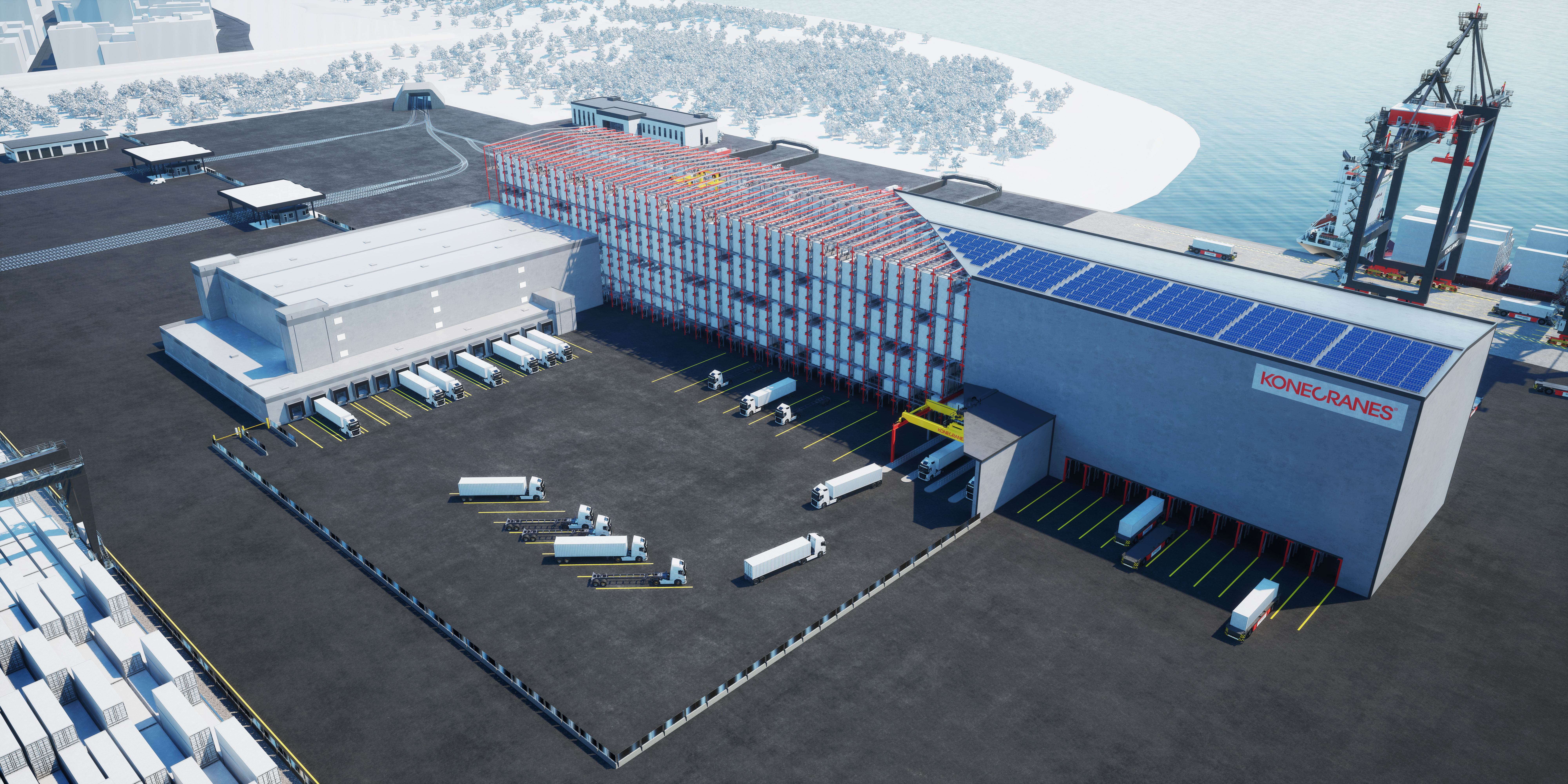

Konecranes Zone

A personalized experience to discover what Konecranes has to offer. You can even design your own terminal concepts and products and when you are ready to talk, Konecranes experts are at your service.

Optimized for container handling industry, MHC and LT products

yourKONECRANES

Data insights, documentation and maintenance management for container handling equipment, mobile harbor cranes and lift trucks.

Konecranes STORE

Your online source for spare parts and accessories for port equipment.