Due to the critical nature of their work, cranes used in nuclear power plants feature redundant systems that prevent dropped loads from any single system failure. To further enhance crane safety and reliability, nuclear cranes are engineered to meet standards that exceed those required for industrial cranes.

By Steve Lawrence, Product Manager, Konecranes Nuclear Equipment and Services

Among these standards are regulations set by the Nuclear Regulatory Commission and American Society of Mechanical Engineers NOG-1, “Rules for Construction of Overhead and Gantry Cranes.”

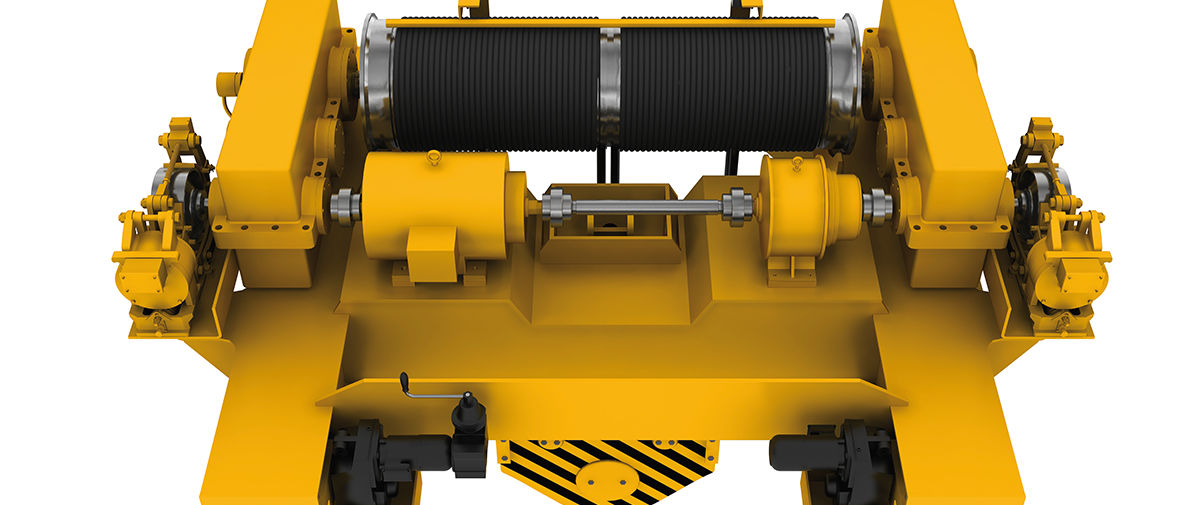

Nuclear cranes that handle critical loads are designed with redundant systems to minimize the impact of a single-failure incident. However, the redundant load path systems of Konecranes nuclear cranes differ from those of other nuclear crane brands, which are designed to catch a falling load with redundant drum brakes or other mechanisms.

In contrast, Konecranes nuclear cranes minimize the uncontrolled movement of the load on the hook by employing redundant hoist gearboxes. In the event of a single failure, this system smoothly transfers the load from one load path to another.

Two independent wire rope reeving systems enhance nuclear crane safety. Other safety features include two-block and hung-load detection and protection and redundant control systems. These redundant systems monitor and prevent cranes from exceeding speed and other operational limits. When limits are reached, these systems set the brakes and alert the operator.

In addition, other components such as load pins and upper blocks and reeving systems are designed for twice the normal design standards, making failure basically inconceivable.

Structural systems of nuclear cranes must be designed more robustly than those of industrial cranes. The structural elements must pass strict quality control standards and additional analysis to ensure that they can withstand the extraordinary stresses exerted by an earthquake and events such as a load hang-up.

Heightened quality control standards include material and welding verifications, material traceability and testing of all load path systems, such as gearing, wire ropes and hooks. Nuclear cranes must undergo and pass more functional and load-testing requirements than industrial cranes.

Lifting systems used by the Department of Defense, Department of Energy and Aerospace utilize similar design concept, due to the expense of the equipment they lift.

Learn more about our Nuclear crane offering