The S-series crane is a highly advanced, precise, and durable lifting tool. With wide variety of hoist configurations and girder designs, it suits many kinds of industry applications and processes, like:

General Manufacturing - Manufacturing facilities must maintain a constant process flow, from incoming prefab or raw materials all the way to packaging and shipping. When any interruption is a production loss, the right lifting equipment will help keep your manufacturing workflow running. The S-series is a robust and reliable crane that also provides the high accuracy needed for assembly work.

Automotive – The ASR and Smart Features increase speed and accuracy, while optimizing material handling and safety in critical automotive processes. Snag Prevention or Hook Centering reduces the risk of collision with equipment or operators nearby. Follow Me makes moving the empty hook or light loads fast, which speeds up material handling and the process in general.

Metals and Steel – In challenging environments full of dust and heat, production must run smoothly without any unplanned interruptions. As a service crane, the S-series is safe, reliable, and easy to use, giving operators the freedom to concentrate on maintenance tasks.

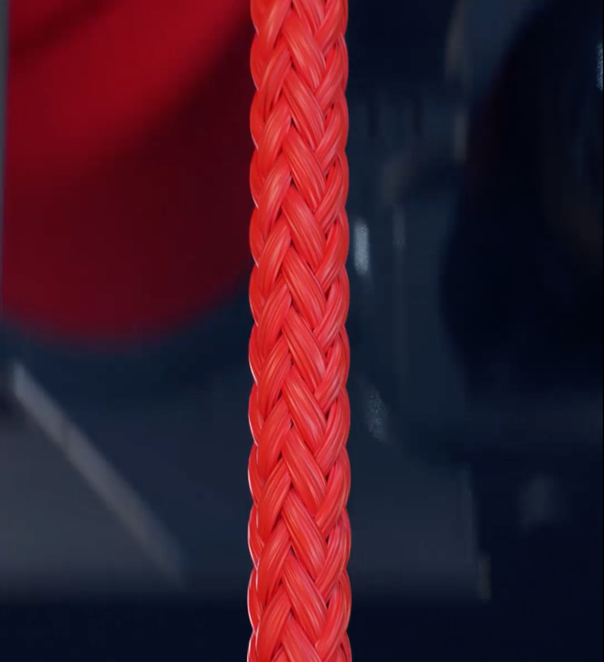

Paper and Forest – In paper mills, load handling is demanding, so it is important that equipment is up and running whenever needed. Maintenance cranes are a critical part of the process. The S-series is an ideal service crane, reliable and easy to use for all kinds of maintenance tasks. Because the drum and synthetic rope do not require lubrication, the process area stays clean.