Designed for efficiency and uptime

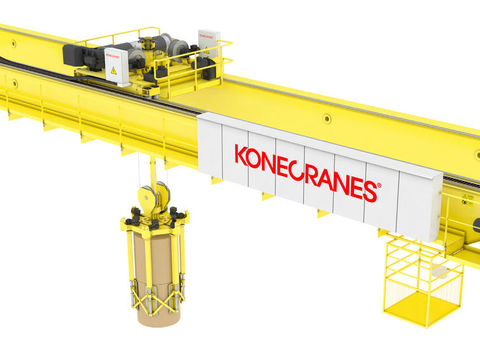

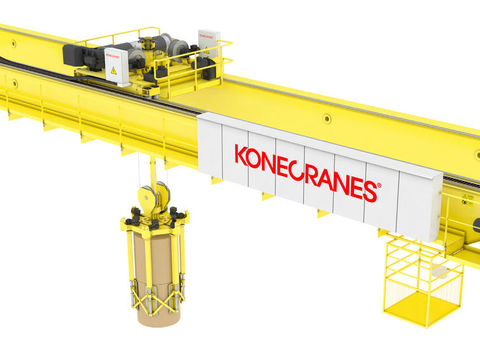

A mechanical gripper crane lifts paper rolls at a paper mill, takes them to storage, where they are usually kept vertically in stacks, and puts them into place for shipping. Handling paper rolls is a critical task in paper production, so they require smooth and efficient travel. A gripper crane is particularly useful when preparing for sea transport, as packing to prevent damage from the movement of a cargo vessel means that paper rolls cannot be lifted by vacuum technology.

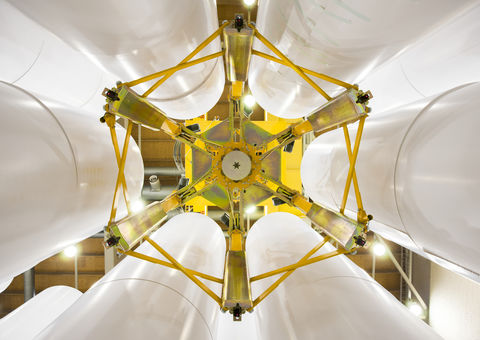

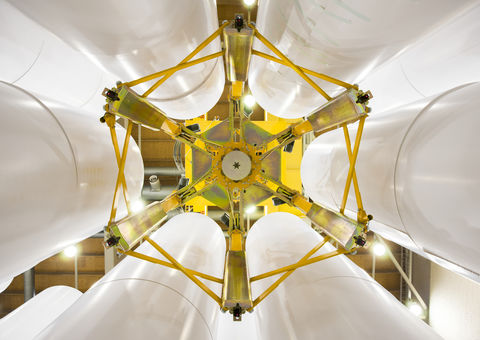

A Konecranes mechanical gripper crane has a gentle grip with six evenly distributed friction pads to minimize roll deformation, and guiding slides to protect rolls from accidental contact with the pads. It uses the latest technology, including smart sensors and other intelligent features, to protect paper rolls from damage during lifting. Crane design improves the use of space in paper storage area and makes retrieval more efficient.

Customer story - Metsä Board Äänekoski Finland

“We had a really tight schedule. The average delivery time for the contractors was down to four months. For Konecranes, that was not an issue, and they delivered the grip on time. We noticed that Konecranes’ people are really professional, the same professionals that we learned to appreciate the last time we worked with them, in 2008. Even our special requests were handled quickly, and production started in September, exactly on time.”

Timo Salo, Project Manager, Metsä Board

Features

We dedicate our unparalleled experience and expertise to help you maximize efficiency and avoid costly problems right from the start.

- Grab paper rolls up to 3.6 meters high

- Moves rolls of various grades and sizes

- Maintenance-free clamping drive unit

- Advanced gripper docking station

- Intelligent sensors for grippers and guiding slides

- Smart Features such as and collision avoidance

- Roll overhang and load drop protection

- Multi-roll handling

- Clamping force adjusted precisely with load cells

- Robust structure and components

Benefits

One of our primary objectives is to reduce the amount of equipment in your process by developing more efficient and less costly ways of using your equipment

- Improved productivity induced by shorter cycles.

- Increased efficiency by Multi roll handling.

- Utilize storage space more effectively by moving different paper grades and roll sizes

- Optimum safety with features like Roll overhang and Load drop protection

- No damage to rolls as clamping force is adjusted precisely with load cells.

- Roll protection with helps of intelligent sensors.

- Robust structure and components

- Industry-focused service and support

Technical Specification

|

Bridge capacity |

7.5 -11 - 15 t |

|

Winch type |

Purpose-built open winch |

|

Weight of trolley |

7 – 8 - 9 t |

|

Span |

25 - 30 – 35 m |

|

Lifting height, max. |

20 m |

|

Bridge/Trolley travel speed |

120 m/min / 60 m/min |

|

Programmable Logic Controller (PLC) and Main User Interface |

Standard |

|

Manual/Automated control |

Radio |

|

Bridge/Trolley power supply |

Festoon |

|

Class of traveling/traversing machinery |

FEM M8/ EN M8 |

|

Electrical braking |

Regenerative |

Automatic, safer and gentle handling

Everywhere you look in the paper and forest industry, you’ll find Konecranes machines at work, such as this mechanical gripper. Our customers know that Konecranes gives them lifting equipment that lasts due to the technical expertise that goes into it and our global service network providing real-time maintenance and upgrades, all leading to the highest lifecycle value.

Get in touch with our experts to learn more about our mechanical grippers for paper rolls