![]() Konecranes is the original service provider for both Konecranes and Demag equipment.

Konecranes is the original service provider for both Konecranes and Demag equipment.

Condition, usage and operating data for efficient maintenance planning

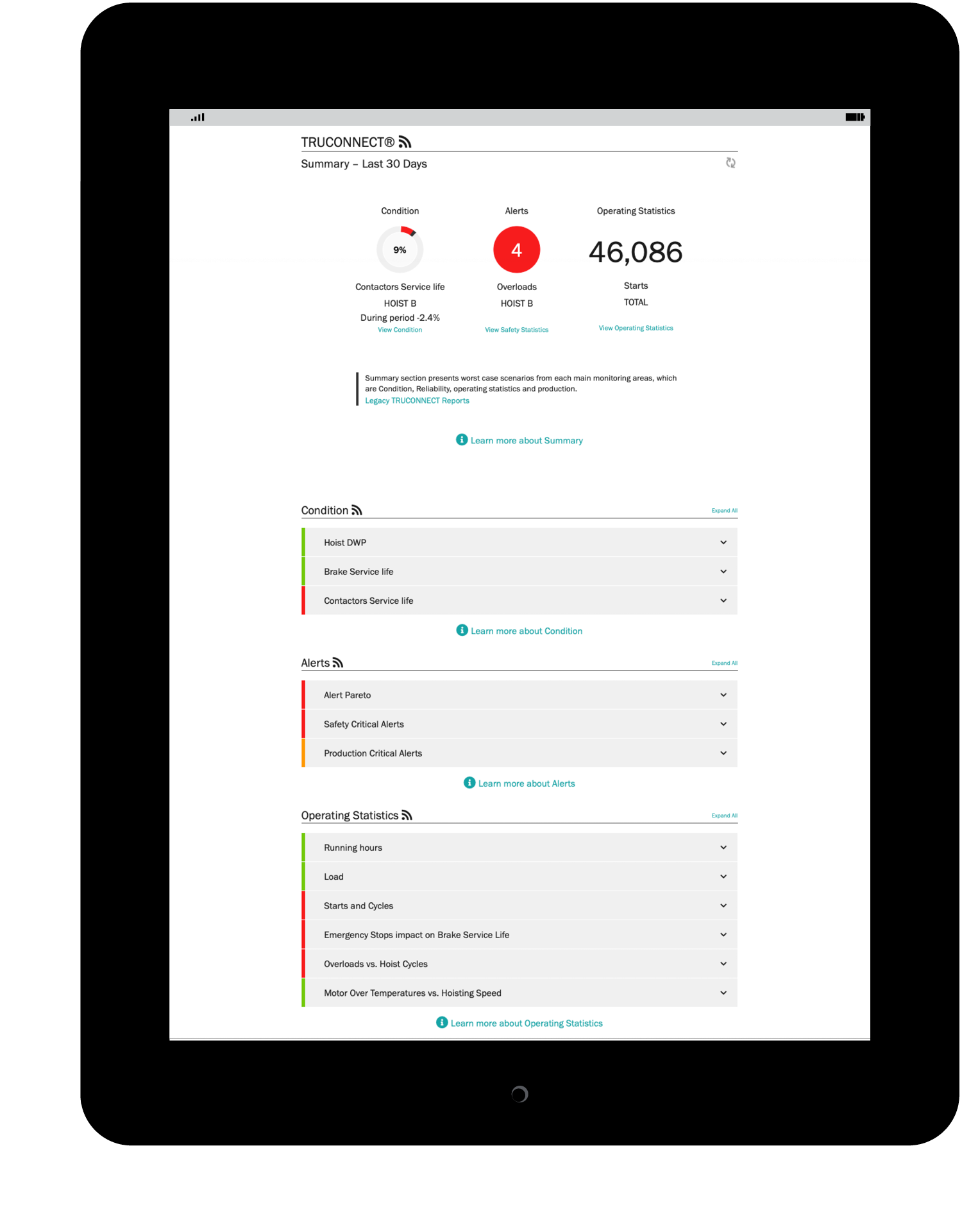

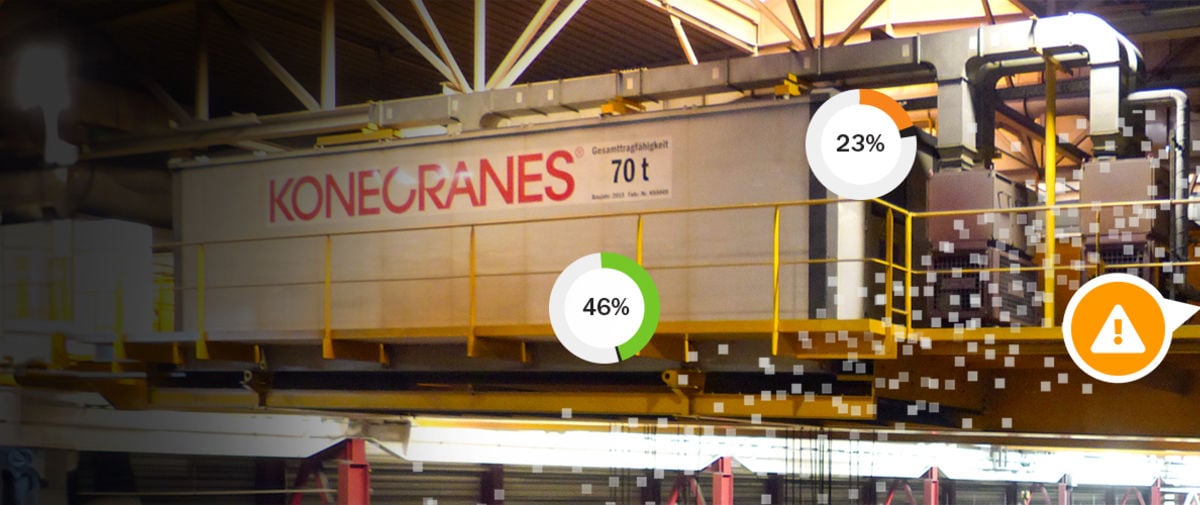

TRUCONNECT is a suite of remote service products and applications to support maintenance operations and drive improvements in safety and productivity.

TRUCONNECT Remote Monitoring is an essential product for incorporating predictive maintenance elements as part of a Konecranes CARE Preventive/Predictive Maintenance program. Remote Monitoring provides valuable usage and operating data that can be used along with inspection and maintenance information for a comprehensive view of equipment maintenance needs and performance.

Analyzing and identifying anomalies, patterns and trends in TRUCONNECT data helps us make informed, component-specific predictions, and prioritize recommendations and actions.

TRUCONNECT Remote Monitoring

TRUCONNECT Remote Monitoring collects condition, usage and operating data from control systems and sensors on a crane and provides alerts of certain anomalies. Remote Monitoring data is used in maintenance planning and in predicting possible component or equipment failure.

TRUCONNECT Remote Monitoring collects condition, usage and operating data from control systems and sensors on a crane and provides alerts of certain anomalies. Remote Monitoring data is used in maintenance planning and in predicting possible component or equipment failure.

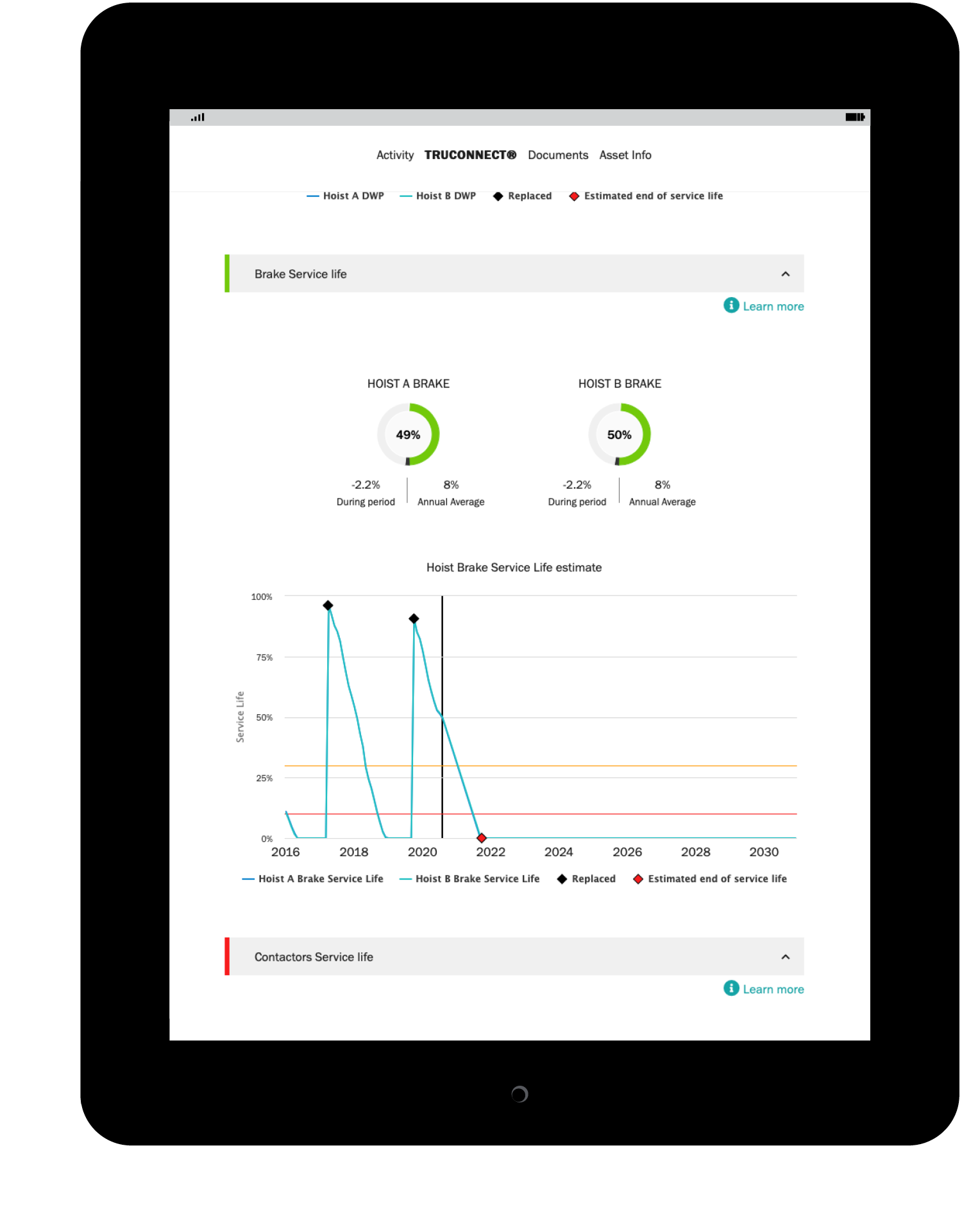

Collected data varies depending on the make and model of your crane, but typically covers condition and expected service life of critical components, running time, lifted loads, motor starts, work cycles and emergency stops. Additional TRUCONNECT options allow certain cranes to be equipped with hoisting brake and/or inverter monitoring.

TRUCONNECT data is accessible on the yourKONECRANES customer portal and includes:

- Safety-related occurrences, such as brake service life, over-temperatures, attempted overloads and emergency stops

- Pareto analysis of critical alerts and faults

- Operating statistics, such as load spectrum, monitoring of hoist jogging, overloads, emergency stops, work cycles and running hours

- Estimates of remaining Design Working Period (DWP) of selected components, such as the hoist, hoist brake, contactors and trolley (SMARTON)

TRUCONNECT Remote Monitoring with alerts based on the equipment/application is required in order to effectively implement predictive maintenance. Remote Monitoring data combined with inspection and maintenance data provided by the maintenance program gives a comprehensive view of equipment maintenance needs and performance.

Safety alerts are delivered automatically by email or text message to notify designated contact personnel of selected safety risk events.

The hoist brake is one of the most critical wearing components in a crane. The brake is looked at during inspections, but with heavily used cranes, the service lifetime of brake wearing parts may end sooner than expected. Additional inspections also require crane shutdown and provide only a snapshot of the current condition of the brake.

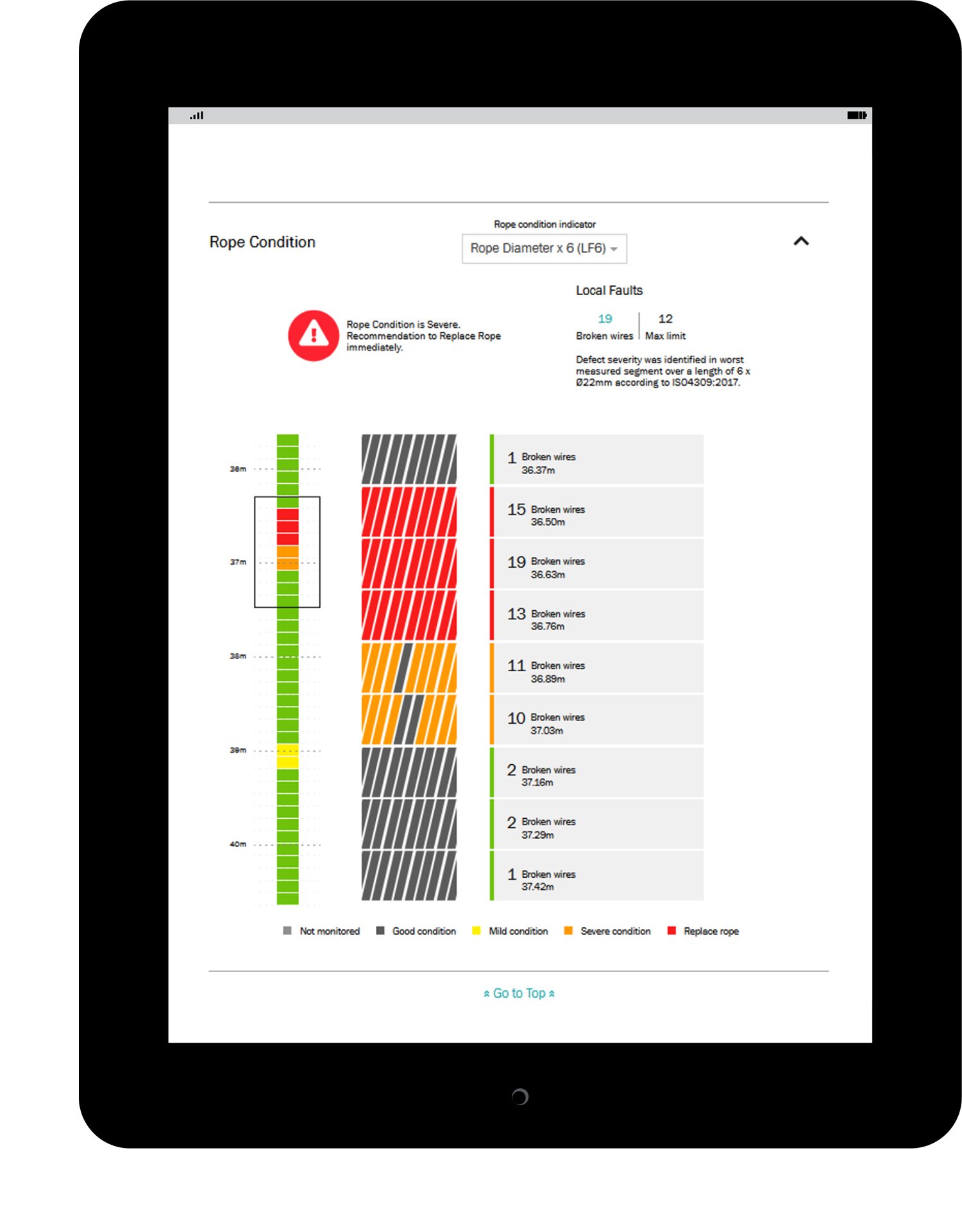

The hoist brake is one of the most critical wearing components in a crane. The brake is looked at during inspections, but with heavily used cranes, the service lifetime of brake wearing parts may end sooner than expected. Additional inspections also require crane shutdown and provide only a snapshot of the current condition of the brake. The wire rope is one of the fastest wearing load-bearing component on a crane. During a typical inspection of a wire rope, only the outer wires and strands can be visually inspected. Magnetic NDT measurements can be performed to analyze the condition of the internal wires, but this requires crane shutdown and a specialist to perform the inspection.

The wire rope is one of the fastest wearing load-bearing component on a crane. During a typical inspection of a wire rope, only the outer wires and strands can be visually inspected. Magnetic NDT measurements can be performed to analyze the condition of the internal wires, but this requires crane shutdown and a specialist to perform the inspection.