We feed the biomass process

A biomass crane transfers material from the reception pocket of a biomass energy plant to storage, continuously feeding the combustion line. Most plants have only one unmanned, fully automated crane for this purpose, so it must be reliable with almost no downtime.

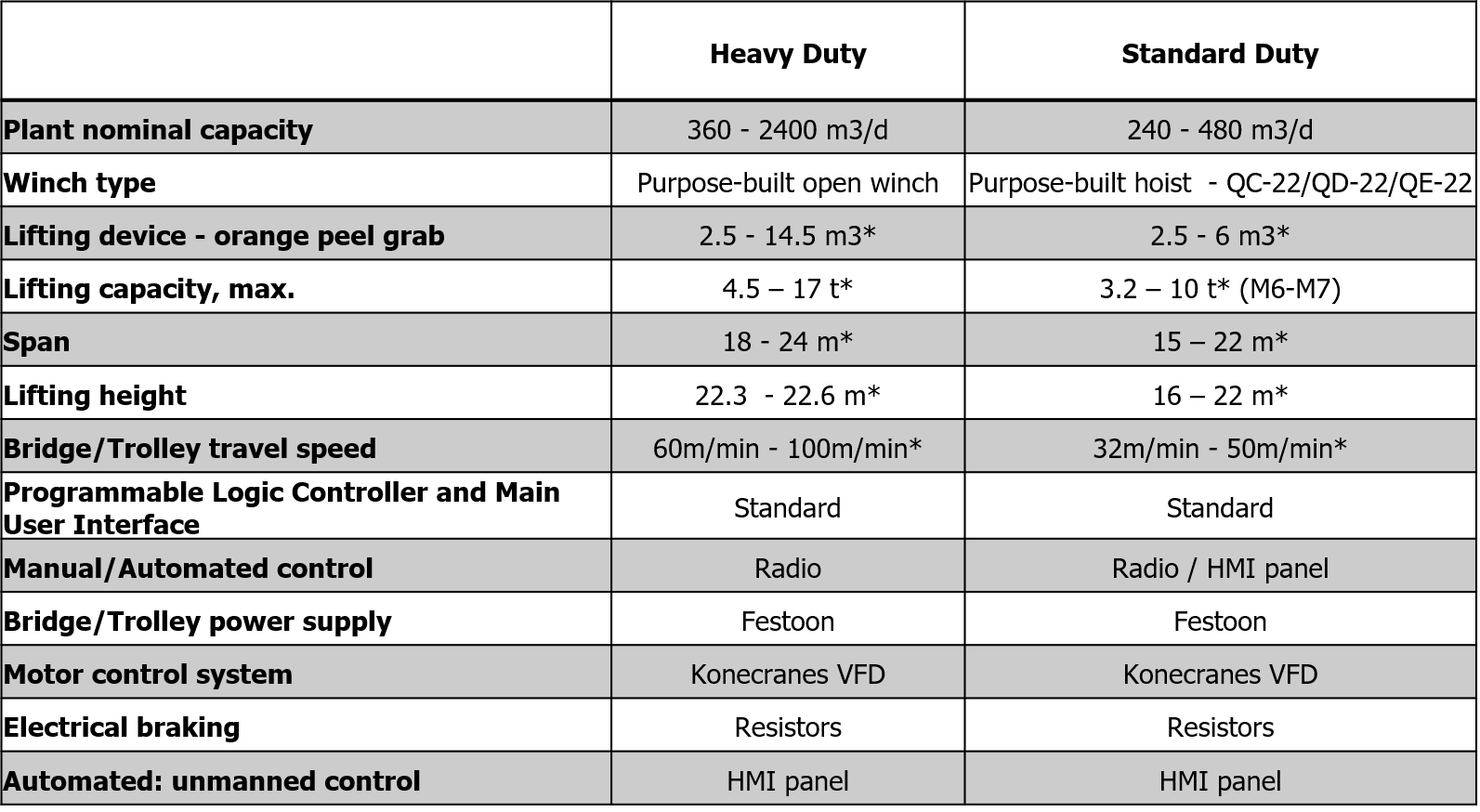

A Konecranes CXT biomass crane is a fully automated, versatile and highly robust crane. Its compact design can help you make more efficient use of your floor space, as well as reduce noise, dust and fuel emissions, all while expanding your fuel storage capacity. The standard duty CXT biomass crane has a capacity of 3.2 to 10 tons, with typical spans from 15 to 22 meters. Heavy-duty biomass cranes have a capacity of 4.5 to 17 tons with a typical span from 18 to 27 meters.

Customer Case - Lorizon, Lithuania

"When using the cranes, we do not need to use other systems like conveyors, tractors or people working in storage area. As the crane is fully automatic, we just need to watch how it is running. It was nice working with Konecranes people as they are professionals and if there will be any project in future, i will be happy to work with them again.”

Jonas Pugzlys, Project Manager at New heat company.

Factors to consider

Below factors can be considered before buying a Biomass crane

- How many tons of biomass are being processed.

- Type and density of biomass.

- Layout of the storage area.

- Daily truck delivery.

- Time to receive and process the biomass.

- Total burning capacity of the boilers.

To be able to quickly adapt in fast changing environment, Konecranes waste-to-energy consulting solution can help simplify and guide complex decision making. We help accelerate building an at-scale Waste to Energy facility and take advantage of economies of scale.

Features

Our knowledge of the role that cranes play in biomass processes has helped us design equipment that is suitable for most biomass handling needs

- Fully automated, operator-free system

- Smart features such as Sway Control

- Active Sway control in Standard duty biomass crane

- Regenerative braking

- Centralized lubrication system

- 2/2 rope reeving or 4/2 reeving

- Advanced crane controls systems

- Tilting limit switch

- Sensors for full automation

- Dual scoop grab as alternative lifting device

- Compact design

- Biomass-specific software

Benefits

The Konecranes biomass crane helps make your process more efficient and sustainable.

- More efficient and safe operations with enhanced performance due to full automation

- Increased floor space usage with compact design

- Reduced noise, dust, and fuel emissions

- Sway Control comes standard and other smart features can be added for safer, faster load handling and more precise positioning

- Energy savings due to Regenerative braking.

- Replaces various types of floor-mounted conveying machines and hydraulic scrapers

- Replaces floor-mounted conveyances and hydraulic scrapers

- Increases fuel storage capacity.

- Reliable and efficient biomass handling with Biomass-specific software.

- Simplify and minimize maintenance costs

Technical Specification

Smarter, Safer , Sustainable

Some of the most challenging crane applications are in renewable energy, and Konecranes has 50 years of experience meeting the tough demands of this industry. Designed in-house specifically for the stresses of lifting, the key components on our cranes work together seamlessly with our crane software, created specifically for biomass cranes, providing you with safe and efficient biomass handling.

Get in touch with our experts to learn more about our biomass cranes.