Tested in harsh environments

A slag handling crane distributes slag – a by-product of the metallurgical smelting process – along conveyor lines as the material is sorted through the slag bunker and loaded into trucks. Slag is highly abrasive and efficient handling requires protection from a harsh operating environment.

A Konecranes slag handling crane is engineered for this specific type of bulk material handling, with corrosion, moisture and heat resistance, as well as the hard durability and reliability Konecranes is known for in tough lifting conditions. Fully automated or operated manually from a central control room, its capacity is 4 to 17 tons with typical spans from 10 to 16 meters.

Customer Case - Mölndals Energi AB, Sweden

Konecranes has proven to be a local, competent supplier with global strength. We are looking forward to long-lasting cooperation with them.

Jan Brännström, Project Manager, Molndals Energi

Features

The Konecranes technical and design teams know slag handling process, constantly striving to integrate features suitable for your lifting needs

- Fully automated, operator-free system

- Integrated weighing system

- Special grab with additional attachment for ferrous handling

- Regenerative braking

- Advanced crane control systems

- Designed for continuous operation

- High rope drum/rope ratio with 2/2 rope reeving

- Deep rope grooves

- Centralized lubrication system

- Compact design

- Sway Control (as standard) and other Smart Feature options

- Surface-hardened wheels with adjustable alignment

- Power cable integration with the drum

Benefits

We build safety, reliability and ease of maintenance into all of our cranes

- Fully automated, operator-free system

- Integrated weighing system

- Special grab with additional attachment for ferrous handling

- Regenerative braking

- Advanced crane control systems

- Designed for continuous operation

- High rope drum/rope ratio with 2/2 rope reeving

- Deep rope grooves

- Centralized lubrication system

- Compact design

- Sway Control (as standard) and other Smart Feature options

- Surface-hardened wheels with adjustable alignment

- Power cable integration with the drum

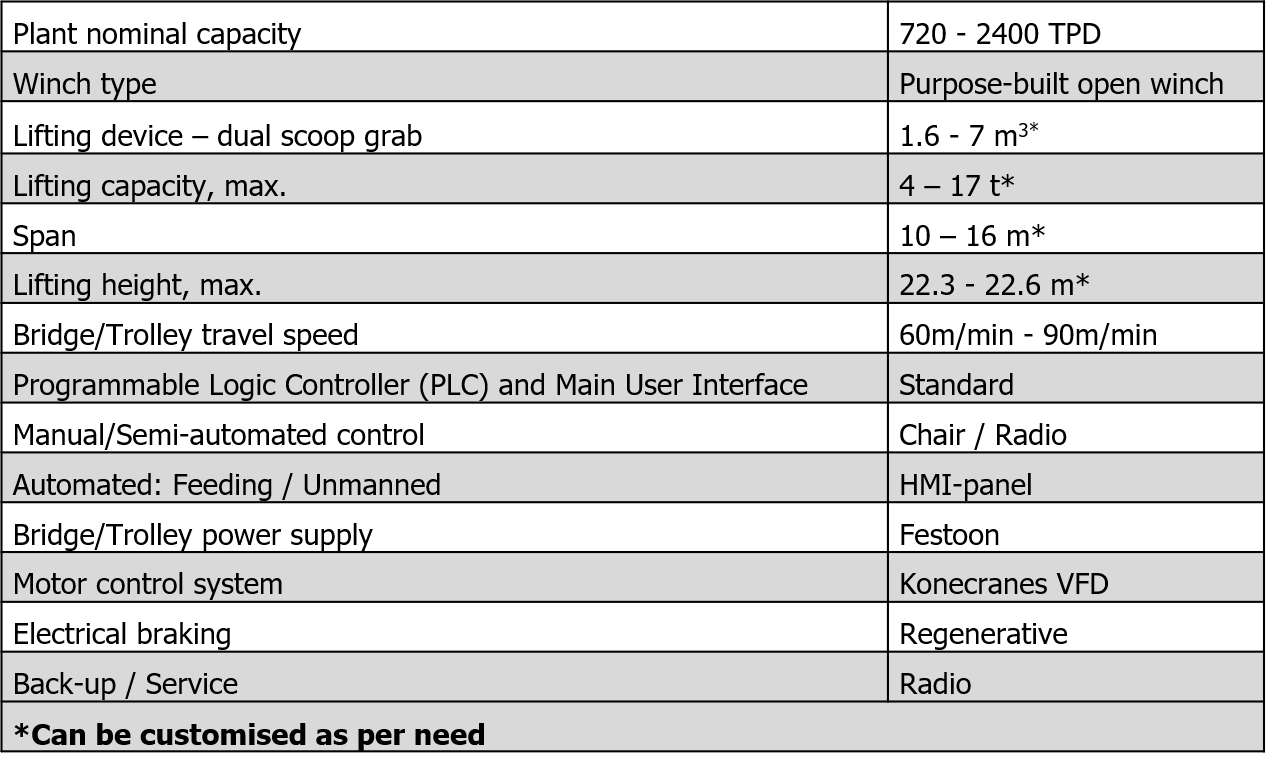

Technical specifications

Strength of Experience

At Konecranes, we know the harsh operating conditions in waste-to-energy and biomass plants, so we engineer lifting and control equipment like our slag handling cranes to endure extreme humidity, dust, and temperature variations. In whatever environment they are used, our cranes maximize safety, efficiency and reliability.

Get in touch with our experts to learn more about our slag handling cranes.