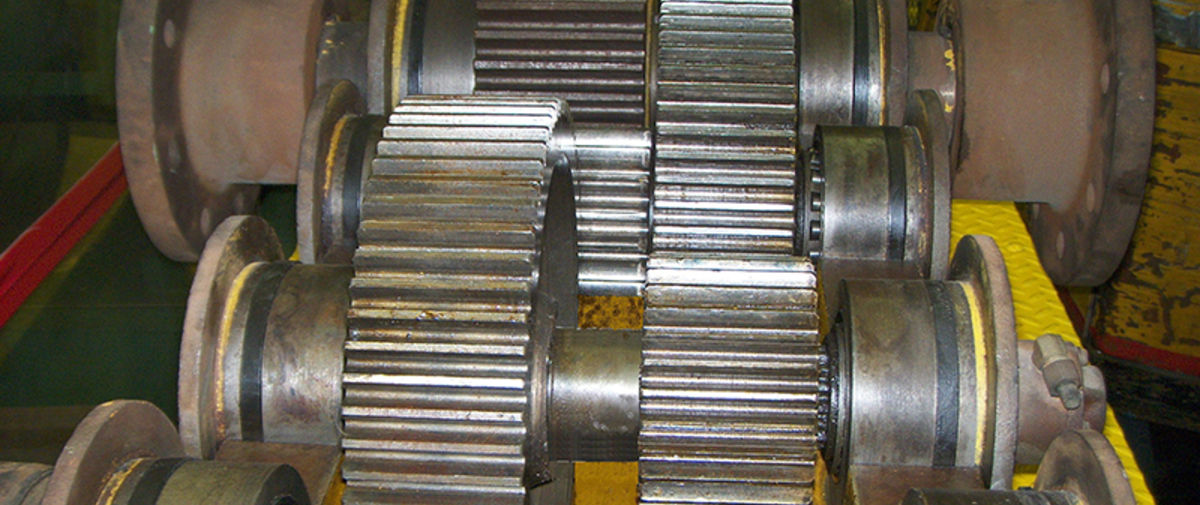

Though gear case inspections are not typically part of standard compliance procedures, they’re essential to crane safety and productivity. Appropriately timed gear case inspections can mean the difference between minimally disruptive, proactive crane maintenance and gear case failure that results in serious consequences. A broken bridge or trolley drive gear case, for example, will prevent the crane from moving, thus halting production and profits. A faulty gear box located on the hoist, on the other hand, is much more dangerous. Failure can lead to dropped loads, injury, and even fatalities.

By Dave Hermanowski, Konecranes Technical Trainer

Like all equipment, gear cases are not designed to last forever. They must be inspected, maintained, and replaced in conjunction with the original design of the crane. Here are three quick ways to decide whether your crane is due for a gear case inspection:

1. Adhere to OEM specifications

According to OSHA, safety and maintenance managers must follow OEM specifications. Some OEMs stipulate that gear case inspections should occur at regular intervals (typically every three to four years), while others say that gear cases are designed to last for a particular amount of time, at which point the hoist and/or gear case must be replaced. It is important to remember that OEM specifications are minimum requirements. They are not necessarily sufficient for the safety and efficiency of your crane.

2. Listen for noise coming from the gear case

When howling or banging sounds emanate from the gear case, several problems could be happening. Gears may be wearing out; backlash, or the widening of the space between the gear teeth and pinion, could be worsening; bearings could be deteriorating; and more. Regardless of the underlying issue, noise should always prompt a speedy gear case inspection.

3. Order gear case inspections every four years

OEM requirements and noise aside, it’s prudent to order gear case inspections every four years. Regular gear case inspections maximise employee safety and reduce long-term costs by minimising unexpected and prolonged breakdowns.

Another way to promote optimal gear case functioning is to conduct an annual oil analyses, the process of estimating the lifespan of a gear case by analysing spikes in steel particles within its oil. Oil analyses is appropriate for all gear cases, but especially for those without inspection covers or removable plates.

What to expect from a gear case inspection

If any of the aforementioned criteria apply to your crane, it’s time to order a gear case inspection. During a standard gear case inspection, a technician will begin by separating the two halves of the gear case. He or she will then remove oil and dirt from the gears with solvent. Next, the technician will examine the gears visually or by liquid penetrant testing, the process of exposing cracks, crevices, and pores using chemical identifiers. Once the equipment has been thoroughly cleaned and inspected, the technician will diagnose issues and make recommendations for repair and crane maintenance.

Though this process can take anywhere from one-and-a-half to five hours (depending on gear case size), it’s well worth the time and effort. Technicians usually replace gaskets, seals, and sealants during inspections, and therefore restore equipment to near-mint condition. More importantly, investing in gear case inspections helps to maximise the long-term health of your crane and the safety of your employees.