What's up there? Hook? Steel structure? Smart crane?

All of them.

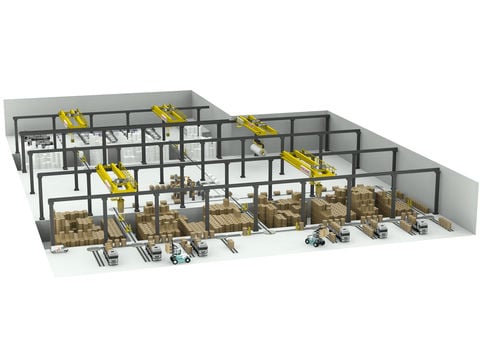

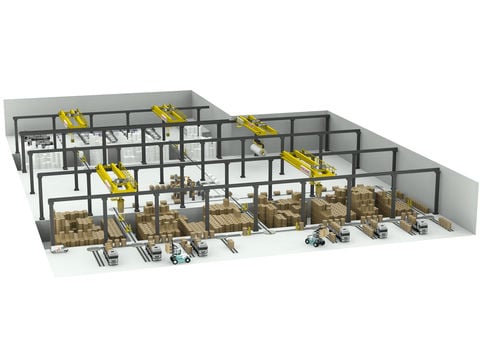

Look up. In every manufacturing facility in the world the ceiling is full of action. You will see uplifts that enable companies' material handling.

Those cranes up there work hard to keep businesses running. For centuries, Konecranes has played a vital role in enhancing productivity within the paper and forest industry. Whether it's hoisting raw pulp into treatment vats or removing finished parent rolls from the main production line, our cranes and services are tailored to ensure safer and more efficient operations.

Who we are

Konecranes has been meeting the needs of the paper and forest industry for decades. Our expertise allows us to offer lifting equipment and services for every part of your operation – starting with the unloading of raw materials and continuing almost every step of the way to the shipping of your finished paper products. We have end-to-end expertise covering planning, engineering, delivery and commissioning as well as maintenance, modernizations and other services.

Our aim is to improve reliability, safety and sustainability in material handling.

PRODUCTIVITY

Konecranes is committed to continuously developing its equipment and services offering by making innovative use of the latest technology. Our cranes are equipped with numerous features designed to enhance safety and productivity. Automated control of movements and cycles minimizes the risk of human error. Konecranes Smart Features further elevate safety, cycle times, and load positioning, proving especially advantageous for repetitive tasks and automated operations. Additionally, safety measures including overload protection, over-speed protection, motion limits, and emergency stop functions are standard features on our cranes.

SAFETY

We are committed to safety; We have put decades of experience in technology and industry into our crane automation and Smart Features, which increase safety and productivity. Konecranes technology is very advanced –Smart Feature like target positioning and various safety features improve the safety. Our aim is to help you achieve the highest level of safety during every shift.

SUSTAINABILITY

We always consider environmental issues throughout the lifecycle of every one of our products. We ensure the efficient use of materials, recyclability and the conservation of energy. Over 98 percent of the materials used to build a typical Konecranes crane are recyclable. Our equipment can be fitted with energy-saving frequency converter technology, feeding up to 30 percent of braking energy back into the network.

Maximizing the productivity

Konecranes has been involved in pulp, paper and wood since the 1920s, and our customers have got to know us as a partner with a clear vision that helps them to succeed. We design equipment for every part of your operation – starting with the unloading of raw materials and continuing almost every step of the way to the shipping of your finished paper products, so your valuable inventory stays in good condition throughout the entire process. Combined with the Konecranes trademark strength, durability, and world-class service, our equipment and service are a wise investment providing highest lifecycle value.

Downloads

Paper and Forest Brochure

Sustainability report

Warehouse management system for paper roll storage