Konecranes is placing the emphasis on its digital offering with a raft of new data-driven products. As its equipment has become increasingly connected, the company has seen a significant shift towards leveraging this connectivity to enhance operations.

There’s been a growing demand for utilising and automating data to optimise performance, streamline maintenance and improve troubleshooting processes. This emphasis on data-driven insights has enabled the company to create substantial value for its customers by ensuring more efficient and reliable operations. ”We encourage our customers to leverage our digital services to achieve the best possible results,” says Sampsa Oja, advanced services product manager port services, Konecranes. ”By utilising tools like TRUCONNECT and CheckApp, you can gain valuable insights, streamline processes and minimise downtime, ultimately staying ahead in a competitive industry. Investing in digitalisation is not just about adopting new technologies but also about enhancing your overall operational strategy for long-term success.”

New offerings

Over the past year, Konecranes has introduced several digital products designed to enhance efficiency and reduce emissions for its customers. These innovations reflect its commitment to providing digital solutions that not only improve efficiency, but also contribute to sustainability efforts by reducing emissions. Konecranes latest API products streamline data flows by automating the connection between different systems, such as those for spare parts and equipment data. This automation enhances overall process efficiency and enables seamless integration.

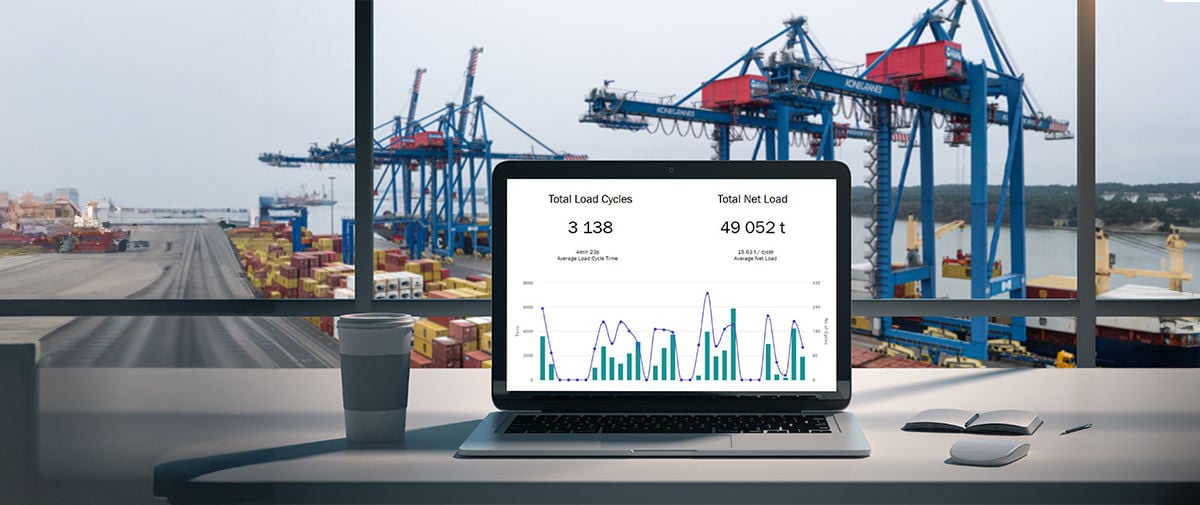

A landmark piece of technology added to the API range is TRUCONNECT which provides a standard and secure way for different applications to connect and share information without user intervention. TRUCONNECT enables customers to compare data on emissions, fuel savings, energy usage and carbon dioxide consumption, allowing them to take informed actions to optimise their operations. It’s accessibe on the yourKONECRANES customer portal and can relay safety-related occurrences, such as brake service life, over-temperatures, attempted overloads and emergency stops. It can also give analyses of critical alerts and faults and operating statistics, such as load spectrum, monitoring of hoist jogging, overloads, emergency stops, work cycles and running hours.

Konecranes has also launched a Spare Parts API. Spare parts of course make equipment ownership and lifecycle management simpler and smarter. But the company wanted to make ordering spare parts part of an automated workflow, whereby parts can be ordered directly from a company’s ERP or similar system. Added to these new products, there is a new customer portal called YourKONECRANES (YKC), where users can access and manage their relevant digital services. YKC combines relevant equipment data insights, documentation and management of the services all into one place. This gives users full and live visibility of all equipment usage data and the ability to manage and modify existing digital service functionalities.

Insight is king

At present, Konecranes says some of its most popular products for ports and terminals are those that provide valuable insights from equipment data. Leading the way are TRUCONNECT and the emerging CheckApp. These products have gained popularity due to their ability to leverage data to drive better decision-making and operational improvements at ports and terminals.

At present, Konecranes says some of its most popular products for ports and terminals are those that provide valuable insights from equipment data. Leading the way are TRUCONNECT and the emerging CheckApp. These products have gained popularity due to their ability to leverage data to drive better decision-making and operational improvements at ports and terminals.

Konecranes is continually exploring new ways to create value through its expanding range of digital products. But like most equipment manufacturers now, the focus is increasingly on leveraging advanced technologies, including AI and machine learning. By using AI and sophisticated algorithms, the company plans to deliver more proactive and efficient maintenance and inspection solutions. According to Mr Oja, these enhancements will help provide customers with even greater insights, optimising equipment performance and reducing downtime. “Our commitment to innovation ensures that we remain at the forefront of the industry, continuously improving our services to meet the evolving needs of our customers,” says Mr Oja. He added that the key takeaway message should be the importance of staying up-to-date and being willing to invest in digitalisation opportunities at individual ports and terminals. “Embracing digital solutions can significantly enhance operational efficiency, improve maintenance practices and ensure optimal outcomes,” he concludes.

This article was published in the Greenport magazine Summer 2024 edition.

At present, Konecranes says some of its most popular products for ports and terminals are those that provide valuable insights from equipment data. Leading the way are TRUCONNECT and the emerging CheckApp. These products have gained popularity due to their ability to leverage data to drive better decision-making and operational improvements at ports and terminals.

At present, Konecranes says some of its most popular products for ports and terminals are those that provide valuable insights from equipment data. Leading the way are TRUCONNECT and the emerging CheckApp. These products have gained popularity due to their ability to leverage data to drive better decision-making and operational improvements at ports and terminals.