Warehouse Management Systems (WMS) are the cornerstone of efficient warehouse operations. But what exactly is a WMS, and what functions does it perform? A WMS is a software application engineered to streamline and optimize warehouse tasks, from receiving and inventory management to order fulfilment and shipping.

As highlighted by industry technology authorities like Gartner, WMS's purview of warehouse operations encompasses various activities, including receiving, put-away, stock locating, inventory management, order picking, packing, shipping, and more. However, it's essential to recognize that not all WMS solutions are alike. The effectiveness and breadth of functionalities can vary significantly among different providers.

WMS is crucial for effective warehouse management

The scope of the WMS is not set in stone – there are multiple variations between WMS providers. This means that some WMS solutions can cover all these areas, some of these areas, or even more. From the activity perspective, this is the scope of the warehouse operations in WMS – how many activities can the system cover?

Another question is how effectively the system can perform the given activity. There's more to it than that. You must consider the scope of this activity's process and what solutions the WMS can offer for a particular activity or task.

For example, regarding inventory management, how much inventory management can the WMS cover? And what does inventory management even mean in this context? And what about ERP (Enterprise Resource Planning), which processes ERP management? Which system is doing what?

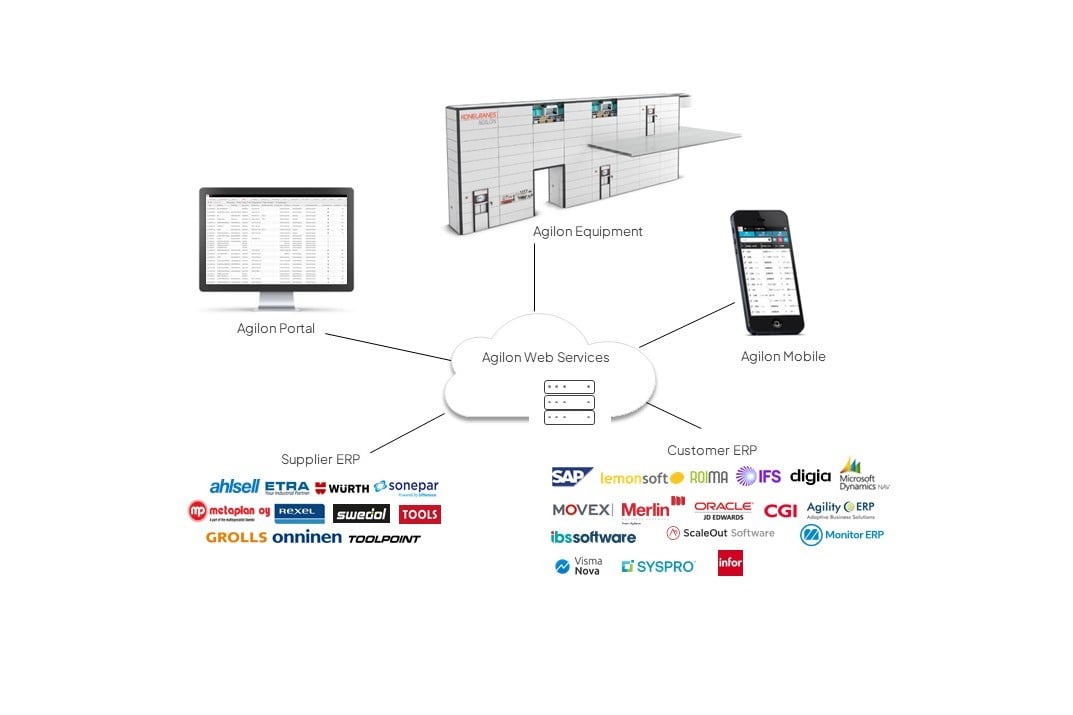

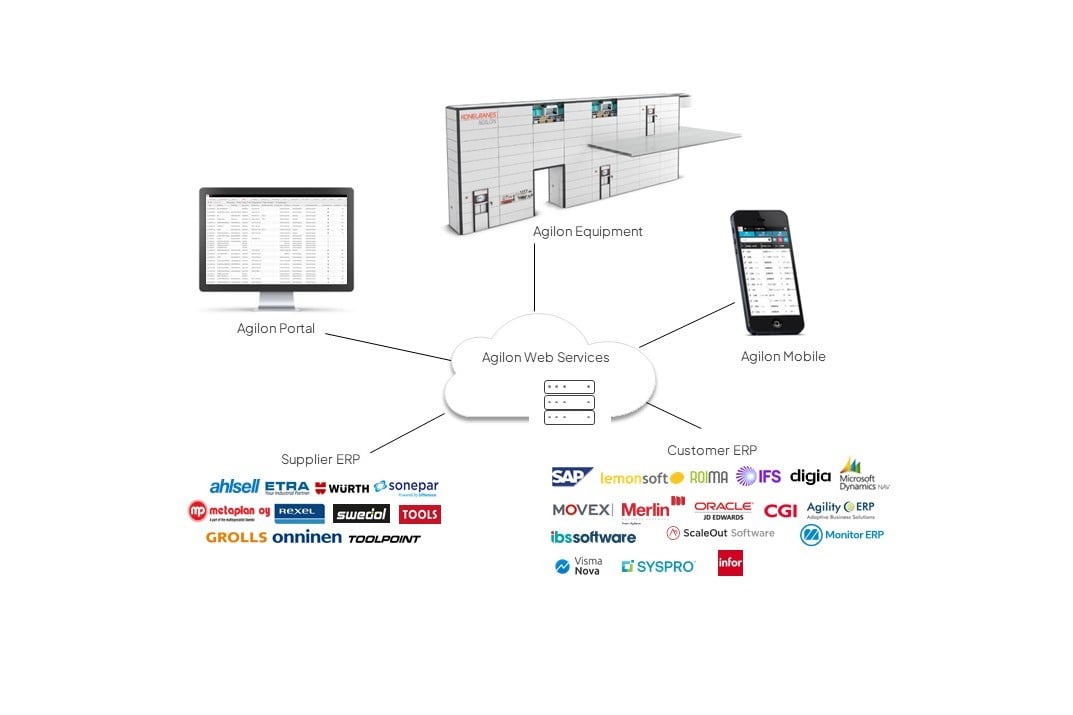

Typically, warehouse-related operations are divided between ERP and WMS if you have a WMS in your warehouse. There might also be other systems, but the warehouse's central split of tasks is between ERP and WMS. ERP is built for business purposes, so the WMS is built for warehousing. In this sense, the WMS performs warehouse-related tasks more effectively than ERP. In this context, WMS is smarter than ERP. If you're ready to unlock the full potential of your warehouse operations, explore the benefits of Agilon WMS today. How smart is WMS, then?

The scope of the WMS is vast. Let's delve into inventory management. According to Investopedia, inventory management is a process of ordering, storing, using, and selling a company´s inventory.

We will use this definition as a guideline to distinguish between WMS and ERP in the inventory management process.

- Ordering: The traditional WMS manages the inventory levels but does not take action in the ordering process. ERP usually manages this.

- Storing: The WMS is typically responsible for the storage process. There is no debate on this. The WMS updates the ERP through the interface on stock balances and transactions.

- Usage: WMS is responsible for using or distributing the materials, i.e., manufacturing or shipping them to customers. From the process perspective, this counts as picking, packing, and shipping. Replenishment can also be one of the processes.

- Selling: WMS is responsible for the shipping process and, in some cases, for transportation management or some part of that. If selling involves money, it is always managed by ERP.

According to Gartner, while WMS is typically responsible for inventory management, the extent of its responsibility varies. This depends on the WMS's range of inventory management areas and how effectively it handles them. There is no standardized requirement for the number of areas a WMS should cover to manage inventory officially.

What can Agilon WMS do?

Agilon WMS and automated storage offer many capabilities beyond inventory management and ordering.

Let´s continue with inventory management and analyse the ordering process further. The ordering process is one of the most critical processes in your company and is the backbone of your P2P process (Purchase-to-pay). You must have the correct materials in stock at the required quantity, quality, and time. Otherwise, your business will suffer from poor on-shelf availability, delayed deliveries, and slow ITO (Inventory Turnover), increasing the capital in your inventories. On top of this, it increases the number of cancelled deliveries (lost sales) and obsolete stock.

Agilon WMS plays a significant role in the ordering process by taking over the activities from ERP and managing them independently. You can automate the ordering process with Agilon WMS by managing the inventory levels, re-ordering points and lot sizes, and sending Purchase Orders (POs) directly to your suppliers. This leads to the automatic management of the ordering process by Agilon WMS, which updates ERP through an interface. In short, this is the perfect example of digitalization.

This was only the system perspective – you can take this further. Agilon WMS with automated storage can change the physical process as well. In practice, this means that your suppliers can make the shipments directly into your automated storage without any effort by your people. This can be done at your goods receiving area, outside your building. In this way, your suppliers do not need to come inside. Agilon WMS comes with Agilon automated storage, and you can utilize the benefits of Agilon WMS in your warehouse.

Our takeaways for you

We can help you identify the critical processes for your warehouse operations and share our expertise to ensure your success. Review your KPIs and reflect on which methods are affecting these.

- Thoroughly understand the end-to-end process, even if other departments are involved.

- Using WMS rather than ERP for warehouse management tasks is more efficient.

- Agilon WMS will be used to digitalize most steps. However, the physical process has the potential for improvement.

- Agilon WMS can manage your entire inventory management process.

To discover how Agilon WMS has transformed warehouse operations for businesses like yours, check out our customer success stories:

Learn how Agilon has revolutionized material handling for our customers | Konecranes

Discover how Agilon warehouse automation can transform your operations:

Maximum throughput and 100% picking accuracy with Agilon | Konecranes

Contact us | Konecranes directly to explore more and schedule an appointment for a personalized demonstration of how Agilon could benefit your business.