Technical specifications

| M-series die gripper crane | |

| Crane classification EN 13001 U-class (load cycles) | U7 |

| Crane classification EN 13001 Q-class (load collective) | Q5 |

| Hoist classification (FEM/EN) | M7/A7 |

| Trolley type | 2 coupled open winches |

| Duty cycles gripper | 2 million |

| Load capacity on tool gripper | Up to 66 tons |

| Die dimensions (length) | 1.650-4.850 mm |

| Die dimensions (width) | 1.200-2.850 mm |

| Die dimensions (height) | 1.600 mm |

| Positioning accuracy | +/-10 mm at the gripper |

| Positioning accuracy of the load rotation angle | +/-0.2 degrees at the gripper |

| Span | Up to 40 m |

| Lifting height, max. | 15 m |

| Lifting height with load | 12 m/min |

| Lifting height with empty gripper | 18 m/min |

| Bridge travel speed | Up to 100 m/min |

| Trolley travel speed | Up to 40 m/min |

| Trolley power supply | Energy chain or festoon cable |

| Manual control | Radio/pendant |

Features

Trolley with coupled open winches

Trolley with coupled open winches- Design of all components considering a center of gravity eccentricity of 100mm, related to the max. die weight

- Stable 4-point load suspension with balancing rocker

- Millimeter-precise pendulum-free positioning

- Redundant laser or barcode measuring systems

- Sway Control

- Die gripper with integrated slewing gear

- Uniform utilization of the rope strands due to integrated compensating rocker

- Ropes tested for this application with high structural stability and high breaking load

- Optional rope drive

- Synchronized sensors designed redundantly and are evaluated in a fail-safe programmable logical controller (PLC)

Benefits

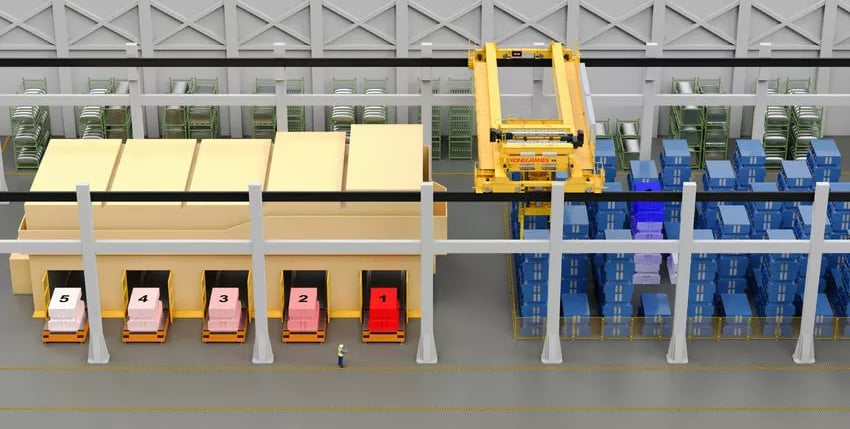

Faster die change

Faster die change- Safer die handling (pick-up, transport and drop off)

- Efficient, space-saving utilization of the available storage area

- Cranes and die grippers are customized as per customer requirements

- Optimized reeving with a minimum of rope sheaves gives a maximized rope service lifetime.

- Different level of automation possible: From manual operation to semi-automatic to fully automatic in combination with the Konecranes Warehouse Managing System

- Intelligent sensor technology recognizes safe load pick-up and detects the surrounding area of gripper to avoid collisions.

- All safety-relevant functions are controlled in performance level d (PL d), category 2, according to EN ISO 13849-1—this also includes bypassing restrictive areas and route-guided target positioning

- Crane and WMS Status visualizations on mobile devices

- Excellent accessibility to all components for maintenance and service activities

- Remote monitoring capability for informed maintenance planning

Technical specifications

| M-series die gripper crane | |

| Crane classification EN 13001 U-class (load cycles) | U7 |

| Crane classification EN 13001 Q-class (load collective) | Q5 |

| Hoist classification (FEM/EN) | M7/A7 |

| Trolley type | 2 coupled open winches |

| Duty cycles gripper | 2 million |

| Load capacity on tool gripper | Up to 66 tons |

| Die dimensions (length) | 1.650-4.850 mm |

| Die dimensions (width) | 1.200-2.850 mm |

| Die dimensions (height) | 1.600 mm |

| Positioning accuracy | +/-10 mm at the gripper |

| Positioning accuracy of the load rotation angle | +/-0.2 degrees at the gripper |

| Span | Up to 40 m |

| Lifting height, max. | 15 m |

| Lifting height with load | 12 m/min |

| Lifting height with empty gripper | 18 m/min |

| Bridge travel speed | Up to 100 m/min |

| Trolley travel speed | Up to 40 m/min |

| Trolley power supply | Energy chain or festoon cable |

| Manual control | Radio/pendant |

Features

Trolley with coupled open winches

Trolley with coupled open winches- Design of all components considering a center of gravity eccentricity of 100mm, related to the max. die weight

- Stable 4-point load suspension with balancing rocker

- Millimeter-precise pendulum-free positioning

- Redundant laser or barcode measuring systems

- Sway Control

- Die gripper with integrated slewing gear

- Uniform utilization of the rope strands due to integrated compensating rocker

- Ropes tested for this application with high structural stability and high breaking load

- Optional rope drive

- Synchronized sensors designed redundantly and are evaluated in a fail-safe programmable logical controller (PLC)

Basic die gripper crane Smart Features

Protected Areas - optional

Protected Areas defines certain zones that the crane cannot enter—such as the press, try-out press, offices or work areas. This improves safety by reducing the risk of accidents and preventing collisions between the crane and other equipment.

Active Sway Control - included

Active Sway Control automatically stabilizes load movements during crane operations. Based on the continual measurement of the rope angle, the operator's speed commands are fine0tuned to stabilize load movement in both trolley and bridge travel. Minimal load sway throughout the duty cycle improves operational safety, load cycle times, ease of crane operation, and produces less wear on crane components.

Hook Centering - included

Hook Centering eliminates side pull during lifting by positioning the bridge and trolley directly over the load. This reduces wear and tear on components, and gives you faster duty cycle times and easier operation.

Target Positioning - optional

Target Positioning brings the load from home position to a predefined target position at the push of a single button. This simple movement increases safety and greatly reduces duty cycle times especially with predictable and repetitive work cycles.

Protected Areas - optional

Protected Areas defines certain zones that the crane cannot enter—such as the press, try-out press, offices or work areas. This improves safety by reducing the risk of accidents and preventing collisions between the crane and other equipment.

Active Sway Control - included

Active Sway Control automatically stabilizes load movements during crane operations. Based on the continual measurement of the rope angle, the operator's speed commands are fine0tuned to stabilize load movement in both trolley and bridge travel. Minimal load sway throughout the duty cycle improves operational safety, load cycle times, ease of crane operation, and produces less wear on crane components.