Konecranes M-series cranes have the following standard features:

- Core of Lifting components, including motor, gearbox and controls specially designed for crane application.

- Extended Speed Range (ESR) allows the hoist to run at up to double the nominal speed, improving cycle times by up to 20%

- Unique hoisting machinery suspension improves component lifetime, supports alignment and performance

- Improved design of rope reeving decreases rope wear and extends equipment lifetime

- Equalizing beam avoids load/bottom block twist with two independent wire ropes instead of one

- No exposed rotating connection shafts or couplings eliminates misalignment, reduces wear and improves safety.

- Load sensors and condition monitoring unit improves safety

- Hook latch trigger makes operation safer and more efficient

- Trolley layout supports compact approach dimensions and uniform wheel load distribution

- Trolley service platforms provide safe access to all inspection points

- Full range of features especially tailored to requirements.

- Intuitive and ergonomic user interface gives operator full control at all times

- Multiple control options:

- radio controls

- computer tablets

- Remote Operating Station (ROS)

- Crane Management System (CMS)

- Energy-efficient special drives where braking energy is fed back into the power grid.

- TRUCONNECT provides real-time data on crane condition and performance

| FEATURES | SPECIFICATIONS |

|---|---|

| Lifting capacity | Up to 70 tons |

| Span | Up to 45 meters |

| Lifting height | Up to 35 meters |

| Runway length | No limitation |

| Hoist speed control | Inverter hoisting with Extended Speed Range |

| Crane control options | Radio remote control with tablet, cabin, or Remote Operating Station |

| Girder design | Box girder |

| Trolley supply | Flat cables or energy chain |

| Compliance | EN A6 to A9/ ISO M6 to M8/ CMAA class D, E & F |

| Certifications | CE, RoHS, CSA |

| Temperature range | -20° C to +60° C |

| Environment | Indoor or outdoor |

| Integrated safety functions | Hoisting safety limit switch, overload protection, hoisting motor thermal protection, hoist over speed supervision, hoist brake opening supervision (with SCM), hoist brake slip supervision (with SCM) |

| Integrated Smart Features | Extended speed range (ESR), Load Floating for hoisting, Shock Load Prevention |

Konecranes M-series cranes offer the following benefits to operators and facilities:

-

High performance and reliability

-

Modular architecture allows adaptation to most applications and industries

-

Easy to maintain

-

Optimized floor space underneath

-

Software control improves processes at all levels

-

Easy and safe to operate for both new and experienced users

-

Improved efficiency, speed, and quality with tight control of material flow

-

Regenerative braking system reduces energy consumption up to 30%

-

Remote monitoring and digital platform, yourKONECRANES, help to plan ahead and maximize uptime

-

yourKONECRANES.com customer portal for access to all crane information

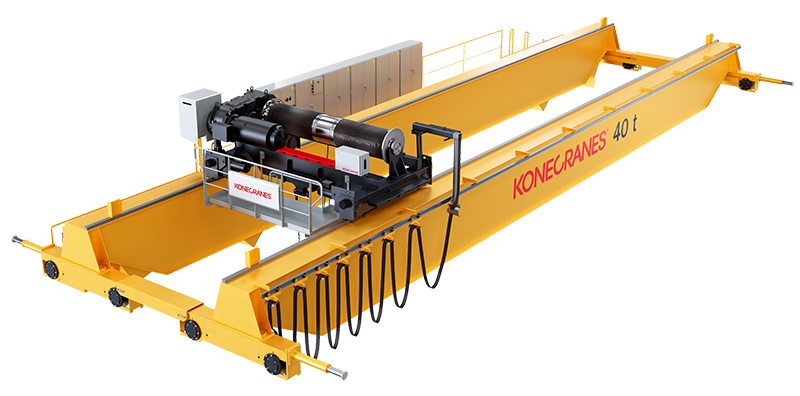

A whole new level of modularity

The Konecranes M-series is the most compact and modular big winch in the business. Built with Konecranes reliability in various sizes for even the most demanding needs. The impact of this crane is big: winch performance and lifetime are taken to a whole new level.