Safer load turning

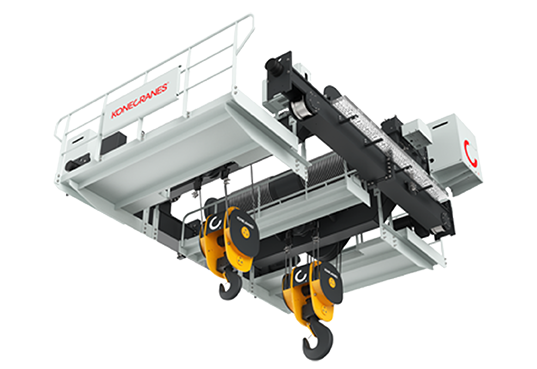

Load turning is a critical process in die handling and it's vital for lifting equipment to perform this process safely and efficiently. During a load turning operation, special measures must be taken due to the unavoidable diagonal pull between the two hoists. In this application, our die handling cranes only allow the load to be turned in a closed system. This means that loads can be turned from trolley to trolley or from one hoist to the next when two hoists are used on a common trolley.

A standard rope angle is +/- 4 degrees, but when a die is rotated much larger rope angles can build up. The Konecranes M-Series crane is perfect for turning loads as rope pulleys are arranged parallel to the trolley rail allowing a rope angle of up to 10 degrees.

To further optimize safety, our die maintenance cranes are equipped with diagonal pull monitoring that is designed to stop crane movement when the permissible rope angle is exceeded.

Technical specifications

| M-series | SMARTON | |

| FEM | M6-M8 | M5-M7 |

| Trolley type | Open winch | Open winch |

| Lifting capacity - main hoist | Up to 63t | 30-63t |

| Lifting capacity - aux. hoist | 20-32t | 20-32t |

| Span | Up to 40m | Up to 40m |

| Lifting height, max. | Tailored | Tailored |

| Bridge/trolley travel speed | Tailored | Tailored |

| Manual control | Radio/pendant | Radio/pendant |

| Bridge/trolley power supply | Conductors/festoon | Conductors/festoon |

| Motor control system | Konecranes variable frequency drives (VFD) | Konecranes VFD |

| Electrical braking | Resistors/regenerative network braking units optional | Resistors |

Features

Two hoist trolley (THT) or separate trolley solutions

Two hoist trolley (THT) or separate trolley solutions- Special features for safer load turning, rope angles up to 10 degrees possible

- Overload protection—system consists of load cells and overload detection unit

- Overspeed control of variable speed hoisting

- Smart Features

- Joystick Radio and pendant for backup and maintenance use

- Second brake for hoisting can be provided

- Frequency controllers for main movements

- Emergency brake

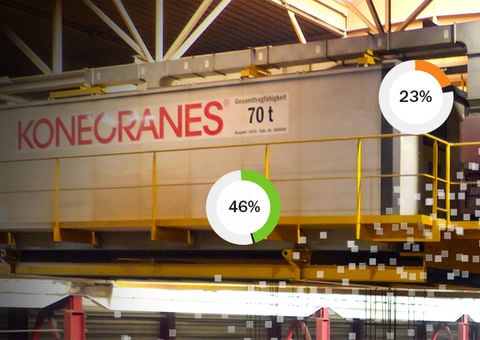

- TRUCONNECT Remote Monitoring

- Electrical room is pressurized and air-conditioned

Benefits

Hoist synchronization provides fast and precise load handling

Hoist synchronization provides fast and precise load handling- Load turning features enable safe operation

- Semi-automated Smart Features help improve safety and productivity

- TRUCONNECT Remote Monitoring provides data for maintenance planning and assessing crane condition and safety

Technical specifications

| M-series | SMARTON | |

| FEM | M6-M8 | M5-M7 |

| Trolley type | Open winch | Open winch |

| Lifting capacity - main hoist | Up to 63t | 30-63t |

| Lifting capacity - aux. hoist | 20-32t | 20-32t |

| Span | Up to 40m | Up to 40m |

| Lifting height, max. | Tailored | Tailored |

| Bridge/trolley travel speed | Tailored | Tailored |

| Manual control | Radio/pendant | Radio/pendant |

| Bridge/trolley power supply | Conductors/festoon | Conductors/festoon |

| Motor control system | Konecranes variable frequency drives (VFD) | Konecranes VFD |

| Electrical braking | Resistors/regenerative network braking units optional | Resistors |

Features

Two hoist trolley (THT) or separate trolley solutions

Two hoist trolley (THT) or separate trolley solutions- Special features for safer load turning, rope angles up to 10 degrees possible

- Overload protection—system consists of load cells and overload detection unit

- Overspeed control of variable speed hoisting

- Smart Features

- Joystick Radio and pendant for backup and maintenance use

- Second brake for hoisting can be provided

- Frequency controllers for main movements

- Emergency brake

- TRUCONNECT Remote Monitoring

- Electrical room is pressurized and air-conditioned