-

| Efficient use of space and time

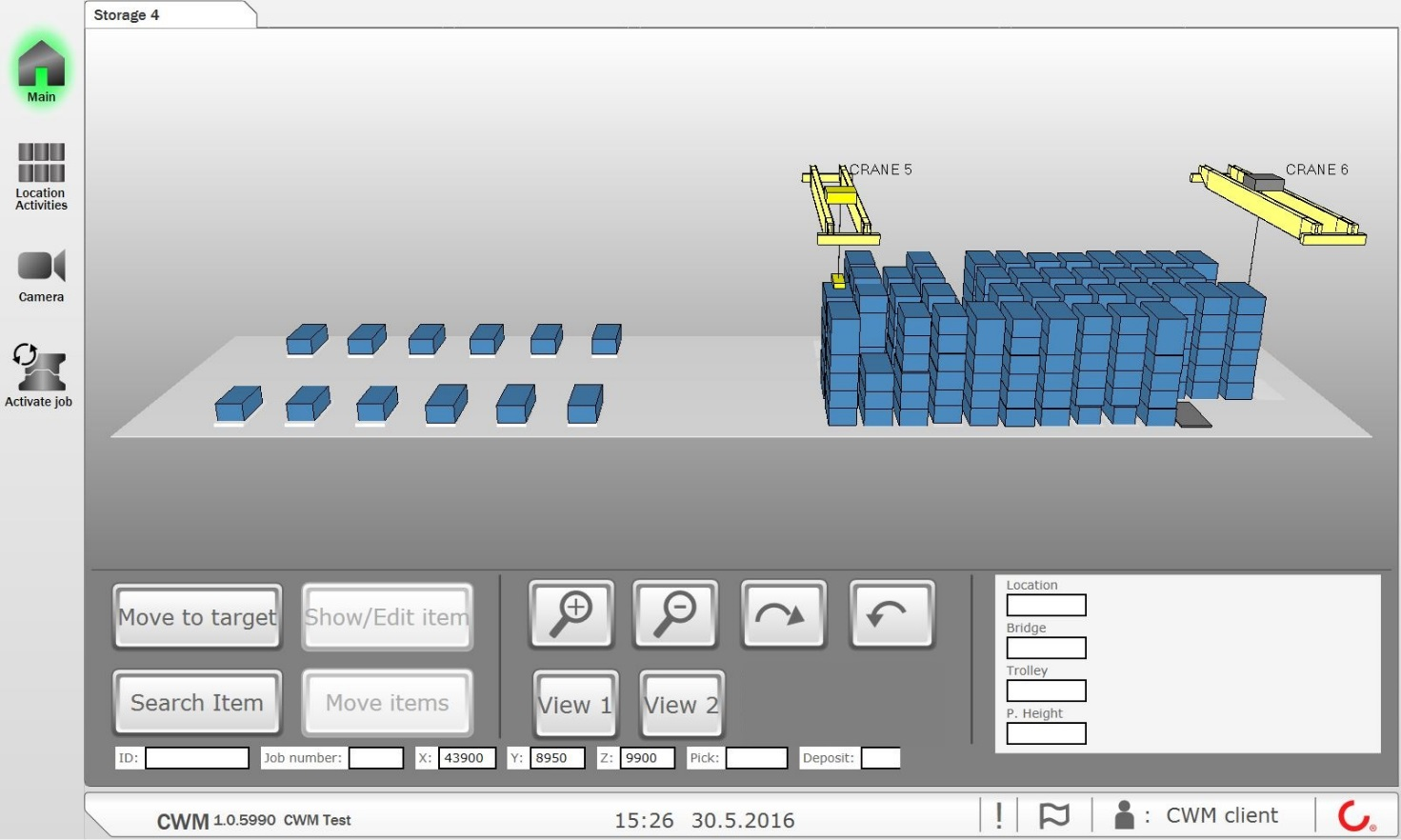

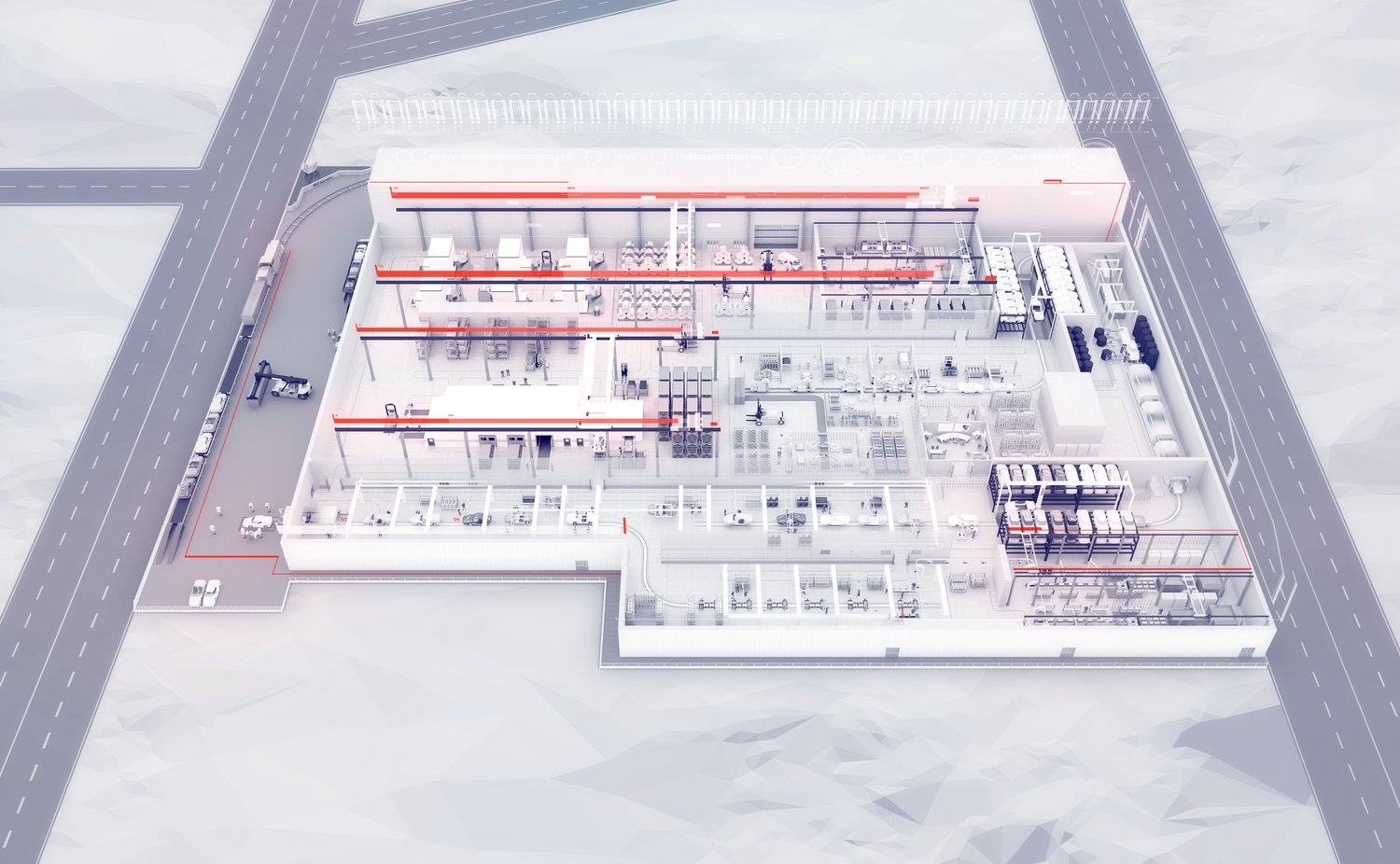

Warehouse automation is the process of automating crane movements. Konecranes Warehouse Management System (WMS) is a PC-based system that controls the management of press line supply and press die storage in an automotive press shop. WMS applications in press shops offer functions such as die location, inventory management, die allocation, die picking and maintenance planning.

Warehouse Management Systems ensure faster die retrieval, easier crane positioning, shorter overall die change cycle times, safer and easier workflows, real-time status reporting, easy-to-use user interface, separate screens for management tasks, reports, stock data, etc. compared to manually controlled cranes.

-

| How it works

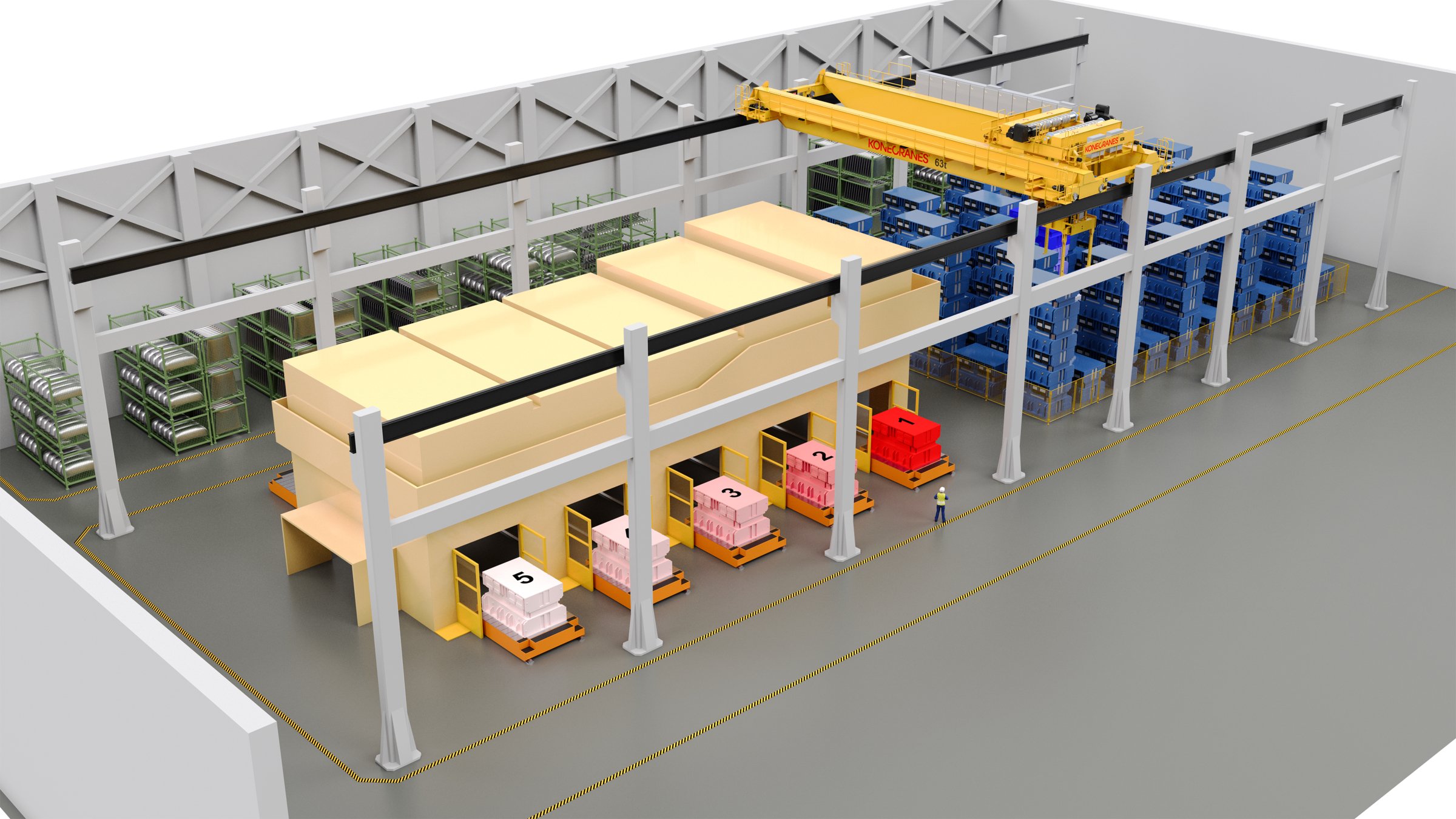

The warehouse management system has an interface to the press control computer (TCP-IP), as well as to the crane control (optical data transceiver). To start the process, a press task with required press die information is sent from press control computer (or MES) to WMS. The warehouse management system (WMS) decides on the optimal storage location and assigns the storage location coordinates, which are transmitted to the crane control. These coordinates are automatically approached by the crane to bring the press die to the designated position in the warehouse or on the moving bolster. After task completion, the crane control reports to the WMS about being ready for further tasks.

Only the newest generation of high-end press machines offers the possibility to automatically supply the media to the dies and the fixing of die on the moving bolster. If the press or the press die do not offer this possibility, this process is done manually.

-

| Structure of the system

The WMS consists of:

• Warehouse management computer (WMS) (stationary)

• Decentralised operating stations

• Mobile operating stationThe WMS has a connection to:

• Crane control

• Decentralised operating stations

• Mobile operating station

• Press host computer

-

| WMS advantages

• Increased storage capacity and efficiency

• Increased reliability and expandability of services

• Shorter cycle times for die changes

• Safer and easier workflows

• Reduced labour costs

• Real-time status reports

• User-friendly interface

• Visualisation on mobile devices, such as smartphone, tablet, etc.

Designed for handling dies

We design equipment's specifically for automotive industries, so your valuable components are handled safely throughout the entire process. Specialized equipment gives you faster and safer work cycles. Combined with the Konecranes trademark strength, durability, and world-class service, our equipment and service are a wise investment providing highest lifecycle value.