Konecranes Portal

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, plus our store for spare parts, accessories and manuals.

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, plus our store for spare parts, accessories and manuals.

A charging crane is critical in steel production. To make steel, a charging crane feeds an electric arc furnace (EOF) in the charging bay and should be able to deliver hot metal to the turret station of a continuous casting machine (CCM) or the ladle furnace (LF). This is a heavy-duty, continuous operation. The same crane can be a backup for the ladle crane if needed. Charging cranes are sometimes called teeming cranes.

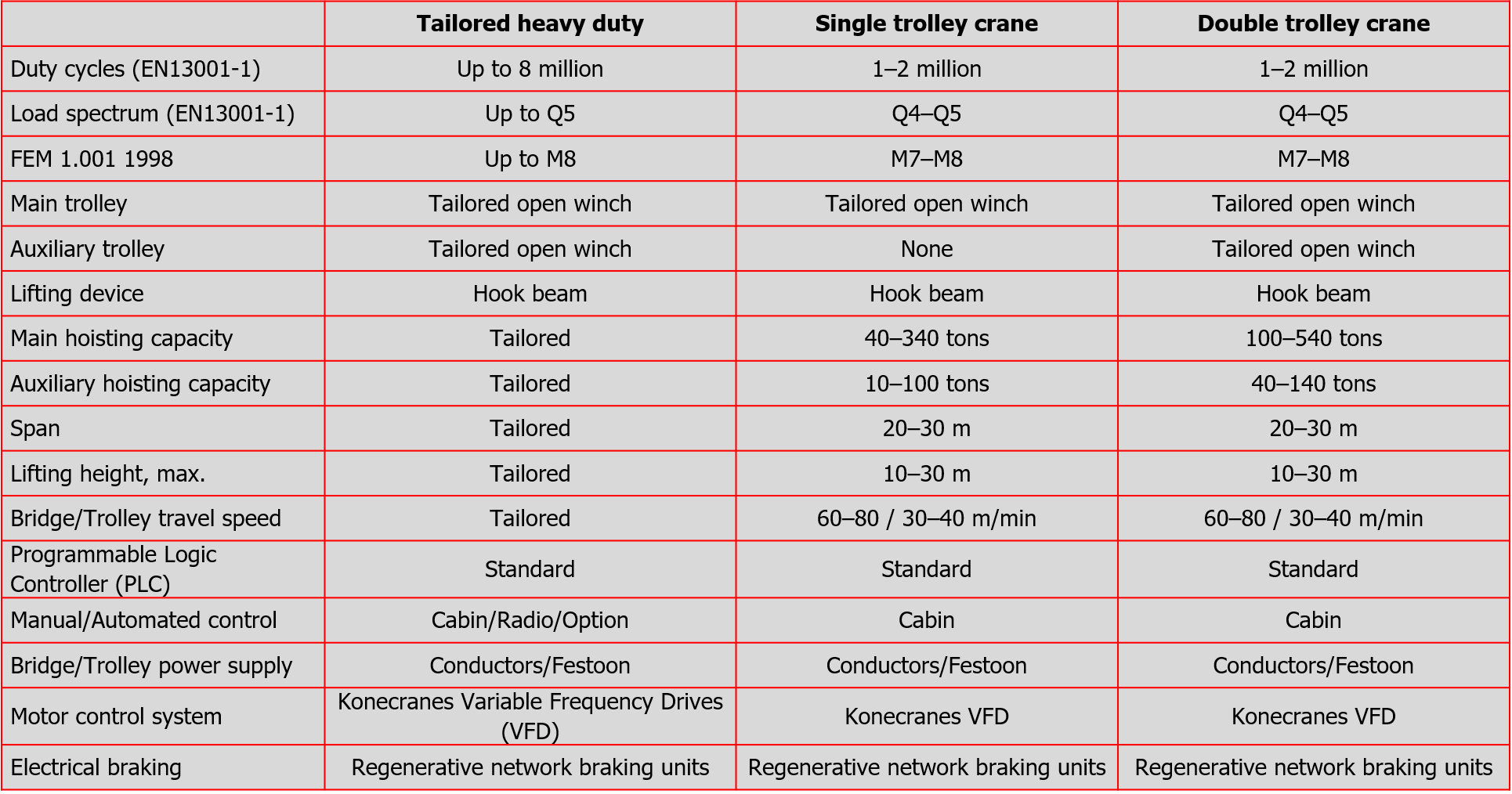

A Konecranes charging cranes is well-protected from the flames and radiated heat of the furnace, as well as the brief, intense heat of the charge itself. Since the load is molten steel, safety and reliability are absolutely essential. Our charging cranes usually have four girders supporting a single double trolley or can be tailored as required, with a lifting capacity up to 500 tons.

“When you have people with experience from a similar project, you don’t need to explain the process to them. They know already.”

Esa Prokkola, Project Manager, Raahe Rautaruukki Corporation

We understand the harsh environment of the steel-making process, so we engineer our lifting and control equipment to endure naked flame, dust, and high heat.

Every konecranes hot metal crane is designed specifically for the unique challenges of this environment

Konecranes works together as a partner with our customers based on a mutual understanding of steel production processes. Our goal is to be a dependable solution provider and support our customers in meeting their production demands while making our cranes easier and safer to use with a high reliability and ease of maintenance, as our customers have come to expect.

Get in touch with our experts to learn more about our efficient, high-performing charging cranes.