A crane lifts every ton of paper produced, and empty spools are returned back to the winding station. Konecranes dry end, coater and winder cranes are dimensioned for handling all process machine output.

Accurate movements are needed when moving heavy rolls around high-speed machines. In addition, crane electrics need to be protected from the warm and corrosive environment.

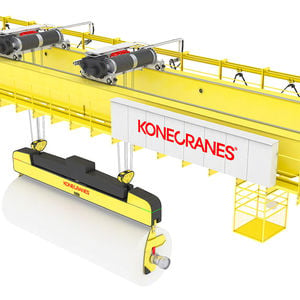

Dry end crane functions

The dry end crane lifts the full parent rolls from the paper machine winding station either onto a storage rack, a transfer car or into the unwinding position of the calendar, coater or cutting machine.

The empty spool shafts are returned back onto the paper machine winder‘s storage rails. Typically, during a normal process run there are one to two roll changes per hour and in addition the same amount of empty spool returning work cycles.

Jumbo roll cranes have multiple purposes, ranging from paper machine maintenance to working as a part of the process machinery.

Intelligent load handling technologies

Smart Features such as Sway Control and Protected Areas help increase the safety and productivity of your mill.