Login

yourKONECRANES.COM

Access your crane usage data, maintenance data and asset details on yourKONECRANES.com. Our cloud-based customer portal gives you a transparent view of service events and activities over any selected time interval.

Login

Konecranes STORE

The Konecranes STORE is your single online source for parts for all crane makes and models. Get access to quick parts ordering, pricing, inventory, lead times and manuals.

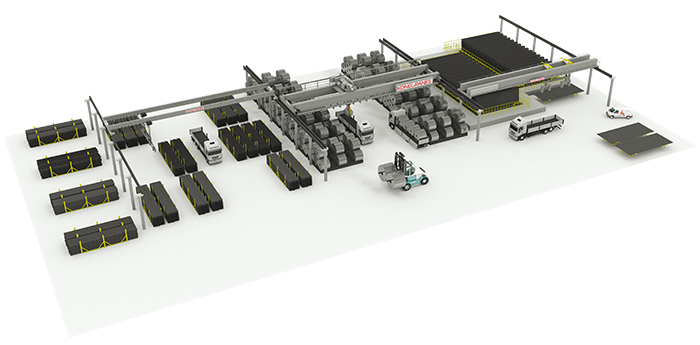

The Konecranes WMS Mobile Robot Management Module (MRMM) controls the material flow of coils outside the storage area. A mobile robot management module is a key component in coil warehousing as it manages and directs the movement of mobile robots for efficient material handling. The Konecranes MRMM can implement several different types of mobile robots.

The Konecranes WMS Mobile Robot Management Module (MRMM) controls the material flow of coils outside the storage area. A mobile robot management module is a key component in coil warehousing as it manages and directs the movement of mobile robots for efficient material handling. The Konecranes MRMM can implement several different types of mobile robots. The Konecranes WMS Yard Management Module (YMM) controls the material flow of coils from the train or truck to storage. The WMS-YMM also controls coil registration and quality checks.

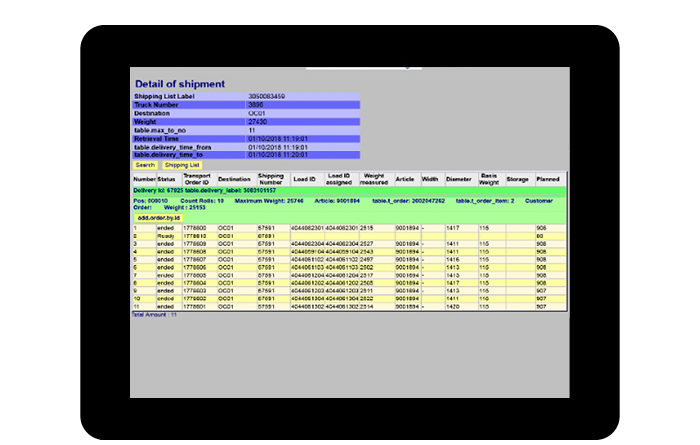

The Konecranes WMS Yard Management Module (YMM) controls the material flow of coils from the train or truck to storage. The WMS-YMM also controls coil registration and quality checks. The Konecranes WMS Production Management Module (PMM) provides special functions for production order management such as the control and management of priorities of production orders and output conveying lines, management of deliveries and delivery positions, and reordering or replacement of coils.

The Konecranes WMS Production Management Module (PMM) provides special functions for production order management such as the control and management of priorities of production orders and output conveying lines, management of deliveries and delivery positions, and reordering or replacement of coils.