What is predictive maintenance?

Predictive maintenance utilizes condition monitoring, advanced inspections, and data analytics to predict component or equipment failure.

How does predictive maintenance work?

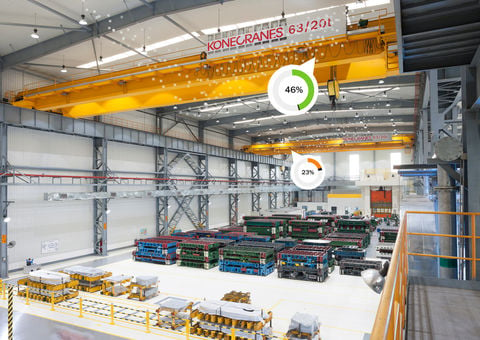

In order to start implementing predictive maintenance, preventive maintenance is supplemented with condition monitoring using TRUCONNECT Remote Monitoring, advanced inspections and analytics. Data provides insights which drive recommendations and actions. A cycle of “data, insights, actions” begins, and as this cycle repeats over time, our maintenance predictions become faster and more precise.

These elements come together in the CARE Preventive/Predictive Maintenance program. Recommendations to repair or replace components are driven by a combination of preventive and predictive maintenance activities. When you add Pre-authorized Repairs, we can proactively perform needed work, saving you both time and money.

Recommendations are shared throughout our customer consultation process and all this information is available in near real-time on our customer portal, yourKONECRANES.com.

What makes up a preventive/predictive maintenance program?

Specific types of service products need to be in place in order to implement predictive maintenance. It is the combination of these products, the use of analytics and our consultation process that makes predictive maintenance possible.

The core of the CARE program includes inspections and routine maintenance. The addition of the following products is required to effectively take predictive maintenance into use.

Services to enable Predictive Maintenance

Remote Monitoring

TRUCONNECT Remote Monitoring provides equipment condition information including estimated remaining life.

Brake Monitoring

TRUCONNECT Brake Monitoring provides visibility into current brake condition, estimates remaining service life.

Oil Analysis

Provides information regarding the condition of internal gear components.

Gear Case Inspection

A Gear Case Inspection and/or an Advanced Gear Case Inspection determines the condition of your crane gears and related components.

Coupling Inspection

Can uncover issues that may lead to failure of load-bearing couplings.

Rope Inspection

RopeQ Magnetic Rope Inspection assesses the condition of a wire rope, including the core and inner wire strands that are not readily visible.

Hook/Shank Inspection

Can uncover issues that could lead to failure of the hook or bottom block.

Design Life Analysis

Calculates the remaining design life of crane structures and machineries based on usage history and the standards used in their design.

CheckApp for Daily Inspections

Helps crane users quickly and easily record their findings when performing pre-shift and/or pre-lift inspections.