Maximizing the productivity

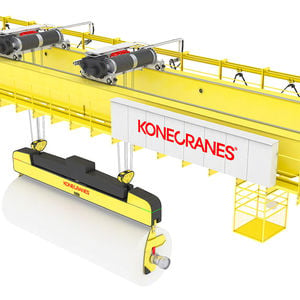

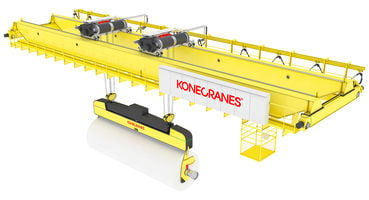

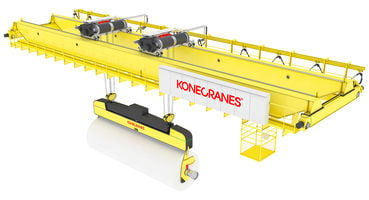

A parent roll handling crane, also known as a dry end crane or winder crane, lifts the rolls of paper produced in a paper mill from the winding station. First, the paper needs to be dried, then passed through calenders to form its thickness, after which it is put on a storage rack, or placed on a transfer car for delivery to another part of the plant for coating or cutting. The empty spool shafts go back to the paper machine winder’s storage rails. Typically, there are one or two roll changes per hour.

A Konecranes parent roll handling crane is dimensioned for handling all process machine output in a standard paper mill. It is designed for accurate movements, needed when lifting heavy rolls around high-speed machines. Made for safety and durability, its electrics are protected from the potentially corrosive, warm and wet environment in which it operates. Larger roll cranes can have multiple purposes across plant processes, including maintenance.

Customer story - Oji Paper, China

" Safety and ease of operation are emphasized in every Konecranes product and service. Konecranes process automation is very advanced. We could even design safety areas in factory before hand. We were also impressed about the safety features of the crane. Cranes play a crucial part in paper production process. A non operation crane will stop the production. We see Konecranes as a strong partner. Not only as a supplier of crane but a long term partner"

Features

We have put decades of experience in technology and industry into all our products, which increase safety and productivity of your business

- Advanced crane controls systems

- High-speed, continuous operation

- Centralized lubrication system

- Intelligent sensors

- Advanced crane controls systems

- Hinged electric boxes

- Designed to work in hazardous environments

- Electric or manual rotating lifting beam

- Semi-automated Smart Features such as Sway Control and Protected Areas

- Compact design

- Lifting speed depends on the load

- Adjustable machine rollers

- Regenerative braking

Benefits

Our aim is to help you achieve the highest level of productivity during every shift.

- More efficient and safe operations with enhanced performance due to semi-automation

- Increased floor space usage with compact design.

- High speed operation improves cycle time.

- Increased efficiency as lifting speeds depend on the load.

- Smart Features such as Sway Control and Protected Areas help increase the safety and productivity.

- Precise handling as machine rollers need installation and removal.

- Energy savings due to Regenerative braking.

- Simplify and minimize maintenance costs.

- Industry-focused service and support

Technical Specifications

|

Load capacity |

15 t – 100 t + 15 t – 100 t(+aux. 2*5 t) |

|

Winch type |

Purpose-built open winch |

|

Travelling speed |

0-50 m/min stepless |

|

Span |

20 – 40 m |

|

Lifting height, max. |

10 – 25 m |

|

Traversing speed |

0-20 m/min |

|

Hoisting speed |

0.4-12 m/min |

|

Manual/Automated control |

Radio |

|

Hoist group |

M5 – M6 |

|

Crane drive group |

FEM M5 (2m) |

Smart. Safe. Compact.

Konecranes is committed to continuously developing the flexibility and efficiency of its paper mill cranes by making innovative use of the latest technology. We research, develop, and implement new product enhancements such as our ever-increasing selection of Smart Features and TRUCONNECT Remote Monitoring to help give you exceptional crane reliability and performance.

Get in touch with our experts to learn more about our parent roll handling cranes.