Konecranes Portal

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, plus our store for spare parts, accessories and manuals.

Konecranes Portal is your single point of access to our digital customer platforms for industrial crane maintenance information and TRUCONNECT data, plus our store for spare parts, accessories and manuals.

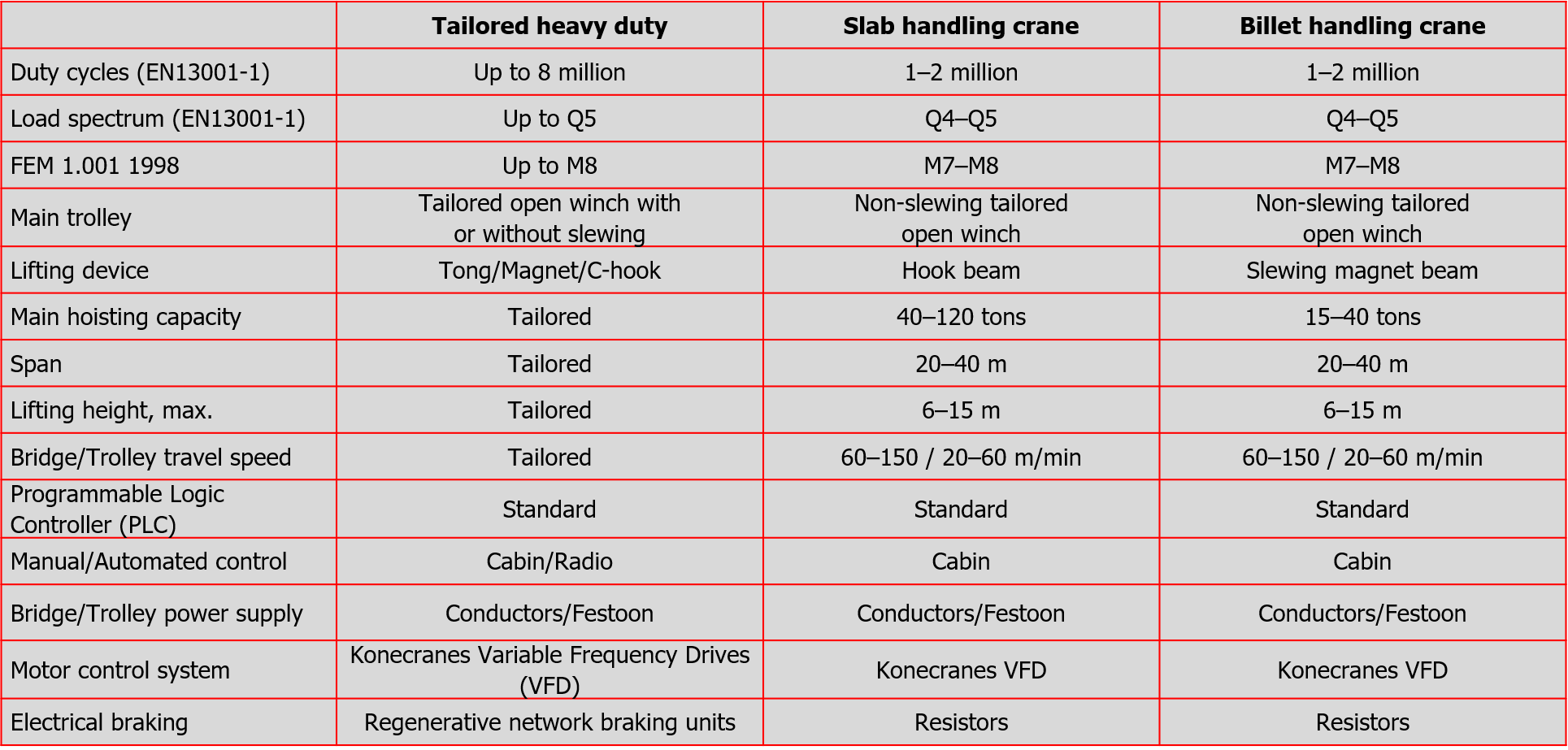

A slab and billet crane is a highly maneuverable electric overhead traveling (EOT) crane that transports large pieces of hot, soft metal - also known as slabs and billets - from the melt shop to its next destination. Because it is so hazardous, the melt shop is usually some distance away from other production locations. The crane feeds the slabs and billets into shaping rollers, takes the metal to be reheated in another furnace before shaping, moves the steel that has been shaped to another conveyor for further processing or delivers it to a storage area.

A Konecranes slab and billet crane is designed move the long distances from melt shop to rolling mill to storage quickly and safely. To cope with the challenges involved in handling either hot and soft metal or cooler pieces, the crane uses a range of Smart Features such as Sway Control, Slack Rope Prevention and Target Positioning that help operators to perform complex movements easily. It can be tailored to your requirements, all the way up to full automation. Standard lifting capacity for a billet handling application is 40 tons and for slab handling is 120 tons.

“Konecranes technology is very good for safety, reliability and the environment, but what is also important to us is their local team behind the technology.”

Piya Chairat, Chief Engineer and Assistant Project Manager, Siam Yamato Steel

We understand how lifting technology is critical throughout the steel production process.

Our long years of experience and continuous investments in R&D drive our innovation

At Konecranes, we build reliability, safety, and ease of maintenance into all our cranes even as we take into account the harsh environment of the steel-making process. We engineer our lifting and control equipment to endure naked flame, dust, and high heat while performing at it best.

Get in touch with our experts to learn more about our durable and highly efficient slab and billet handling cranes.