WMS planning

Simulation models optimize planning

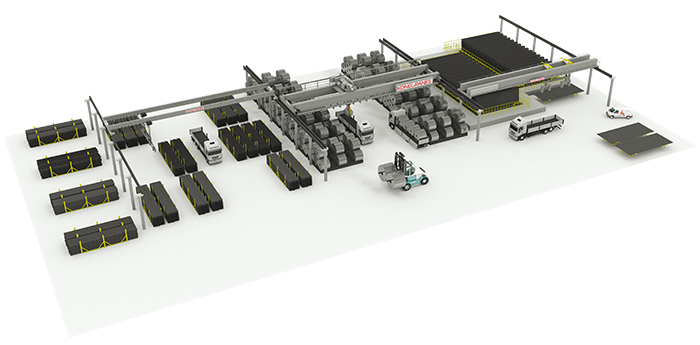

Using different simulation models, we analyze capacity and performance in order to provide recommendations on the system design and capacity, the number of bridge cranes and performance requirements as well as insight on the operational rules of the system.

Why simulation?

- The model provides a detailed view of the proposed system to make sure it meets your specified KPIs. It’s also used for throughput calculations, i.e., what would it look like if we added a second crane on a runway.

- Simulation modelling with 3D animation helps validate the design in terms of crane behavior, stacking height and operational rules.

- The model is also used to optimize coil storage strategies and capacity, mobile robot/conveyor routes and material logistics within the facility.

Digital twin for insights and training

We use cutting-edge simulation technology to create a digital twin of your crane-automated coil warehouse that emulates the crane movements. This virtual model helps operators and engineers gain valuable early insights into the expected performance of the entire system.

Why a crane emulator?

- Can help identify potential bottlenecks, optimize storage configurations, and fine-tune operational procedures even before the physical warehouse is constructed.

- Can be used as a training tool for operators, letting them get familiar with the WMS and crane automation functionalities during the engineering phase.

- Advanced training helps provide a smooth transition to real-world operations, reducing the learning curve and enhancing overall efficiency once the warehouse is operational.

WMS service

Preventive Maintenance Service

Protect your warehouse management system investment with the WMS Preventive Maintenance Service. The service provides support for the Konecranes WMS software during the operation of the system and includes regular inspection and minor adjustments to maximize availability and minimize the risk of downtime. When you require high-level technical expertise, you can take advantage of troubleshooting support during office hours.

WMS Remote Support

When time is critical WMS Remote Support provides quick response for troubleshooting issues that require high-level technical expertise. Minimize unplanned downtime with 24/7 access to our global network of WMS specialists supported by local Standby Service.

In controlled circumstances, and assisted by local Standby Service, a two-way on-line communication with the local WMS system and their operators can be established to expedite corrective action.

The Konecranes WMS Mobile Robot Management Module (MRMM) controls the material flow of coils outside the storage area. A mobile robot management module is a key component in coil warehousing as it manages and directs the movement of mobile robots for efficient material handling. The Konecranes MRMM can implement several different types of mobile robots.

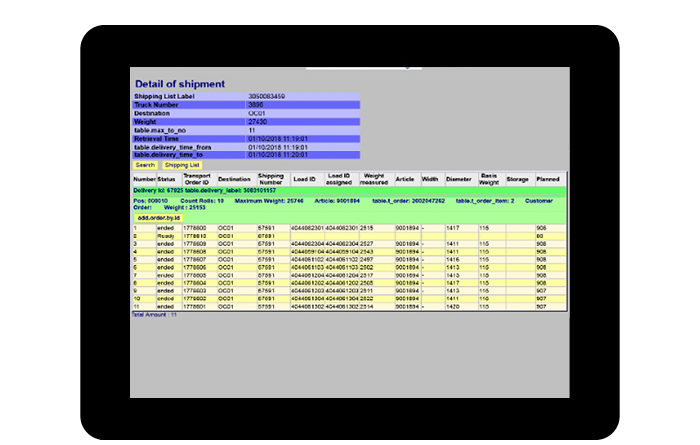

The Konecranes WMS Mobile Robot Management Module (MRMM) controls the material flow of coils outside the storage area. A mobile robot management module is a key component in coil warehousing as it manages and directs the movement of mobile robots for efficient material handling. The Konecranes MRMM can implement several different types of mobile robots. The Konecranes WMS Yard Management Module (YMM) controls the material flow of coils from the train or truck to storage. The WMS-YMM also controls coil registration and quality checks.

The Konecranes WMS Yard Management Module (YMM) controls the material flow of coils from the train or truck to storage. The WMS-YMM also controls coil registration and quality checks. The Konecranes WMS Production Management Module (PMM) provides special functions for production order management such as the control and management of priorities of production orders and output conveying lines, management of deliveries and delivery positions, and reordering or replacement of coils.

The Konecranes WMS Production Management Module (PMM) provides special functions for production order management such as the control and management of priorities of production orders and output conveying lines, management of deliveries and delivery positions, and reordering or replacement of coils.