Login

yourKONECRANES.COM

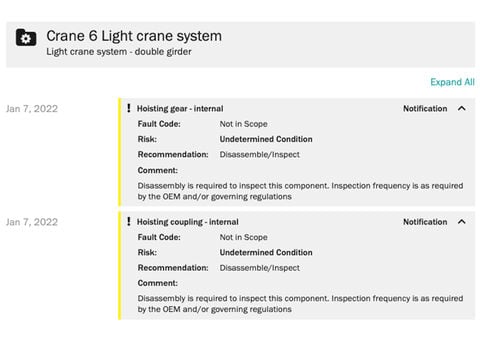

Access your crane usage data, maintenance data and asset details on yourKONECRANES.com. Our cloud-based customer portal gives you a transparent view of service events and activities over any selected time period.

Login

Konecranes STORE

Konecranes STORE is your online source for spare parts, manuals, accessories and select pre-configured lifting equipment.